Kehua Intellient Equipment is a high-tech supporting production enterprise specializing in the development, manufacturing, and sales of various types of thermal intelligent equipment. Our company has advanced technology, experienced technical management personnel, and efficient professional service personnel, as well as refined quality management and a comprehensive after-sales service system. Our company mainly produces high-temperature furnaces,tube furnaces,water-cooled pumps,electric furnaces,industrial room furnaces,intelligent mobile bottom furnaces,smelting furnaces,vacuum furnaces,induction furnace and other products. Our products are widely used in industries such as cupola metal, alloy manufacturing, casting and forging, melting scrap metal, and ceramic manufacturing.

We have a factory area of 13320 square meters with over 80 employees and an annual production capacity of over 500000 units. We establish a strict quality control system, inspect the quality of raw materials, technical design, production processes, and after-sales service, and support optimization to ensure the production of first-class products. We provide one-on-one dedicated personnel to serve you, including assembly and debugging, training, and risk elimination, providing a one-stop solution to your concerns.

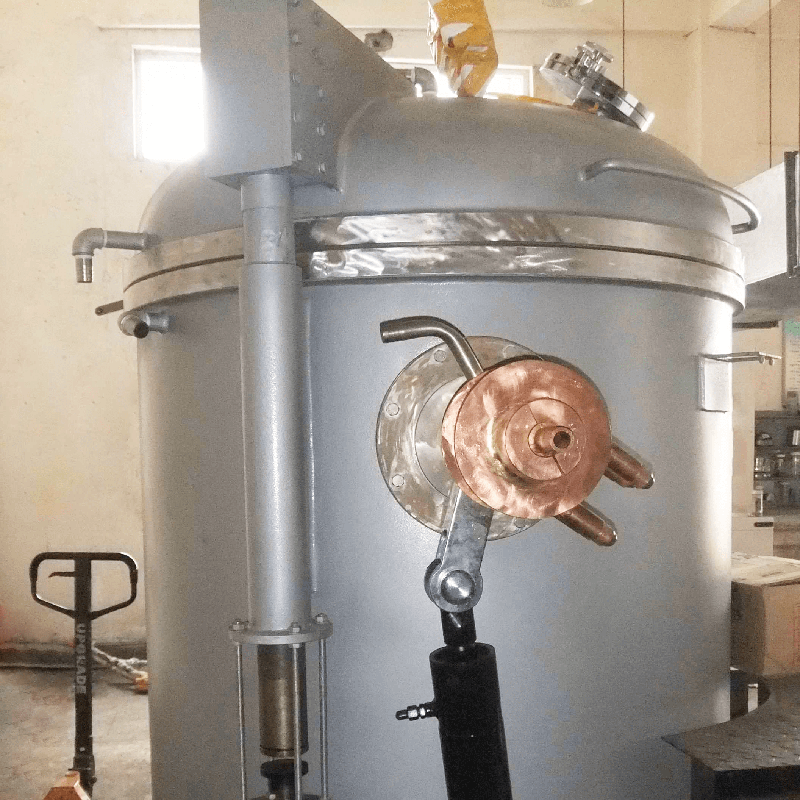

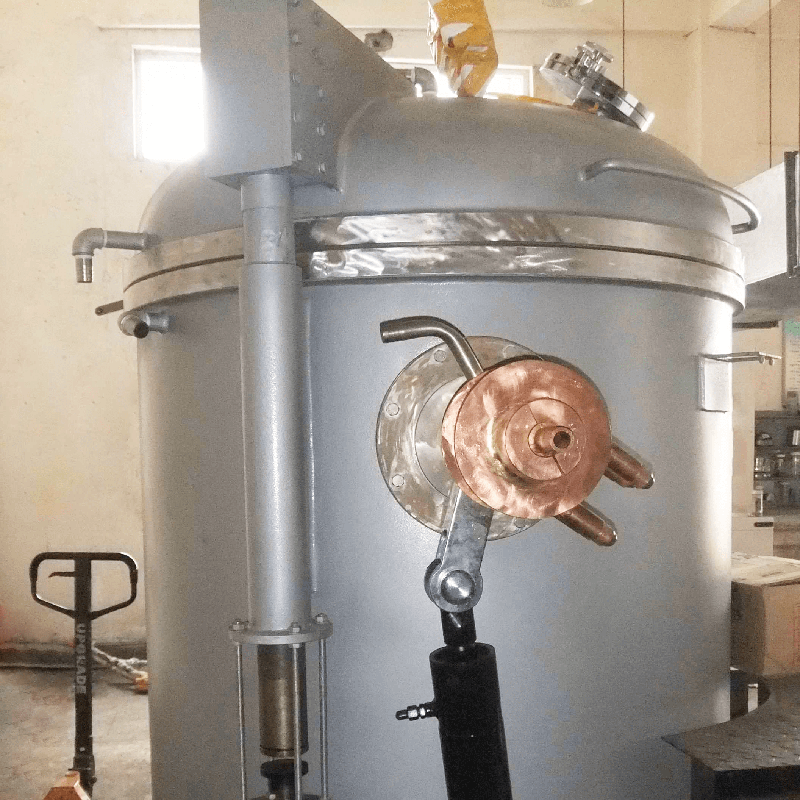

| Product name | tin melting furnace |

| Place of Origin | Weifang, Shandong |

| Machinery Test Report | Provided |

Product Type

| Induction Furnace

|

| Warranty of core components | 1Year

|

Condition

| New |

Core Components

| PLC, Engine, Gear

|

Packing Size(cm)

| 458*163*347 Specific consultation with us

|

| Brand Name | Kehua

|

Export region

| America,Asia,Oceania Pakistan,Samoa,Brunei,Papua New Guinea,Aruba,Congo, Republic of the

|

Weight(kg)

| 2848

|

Power (kW)

| It depends

|

Key Selling Points

| Automatic

|

Voltage

| 110V/220V/380V

|

After Warranty Service

| Video technical support

|

After-sales Service

| Provided Online Support

|

Video outgoing-inspection

| Provided

|

Packaging Details

| Polyfoam filled, Wooden box outside

|

Supply Ability

| 20-100 Set/Sets per Month (See specific model products) |

Lead time (days)

| 40 (To be negotiated)

|

Please note: This table is for reference only, please consult us for specific information.

tin melting furnace is an electric heating device that utilizes electrical energy to generate high temperatures and heat them. Its main working principle is to convert electrical energy into thermal energy, and transfer the thermal energy to the heating material through heating elements, thereby heating it up.

Consisting of a power connector, electronic controller, heating element, and housing. The power connector supplies electrical energy to the electronic controller, which controls the operation of the heating element based on the required temperature setting and actual temperature situation of the heating material.

Perfect after-sales service system.Provide assembly and commissioning, training and eliminate risks, one stop solution to your worries. Quality Guarantee: 1 year. During the warranty period, accessories are provided free of charge; after the warranty period, accessories are provided in time at a preferential price and guide installation and commissioning.

tin melting furnace---FAQs Guide

1.What is the shell material of the tin melting furnace?

The shell material of an tin melting furnace typically consists of steel, stainless steel, or cast iron.

2.If I purchase your tin melting furnace,can I have my logo on the machine?

Yes, of course. We can not only offer standard machines, but also customized machines according to your requirements. And we can also put your logo on the machine.

3.As a tin melting furnace manufacturer,do you provide other supporting tools besides medium frequency induction furnace, and what are them?

Yes, according to the customer requirements, we provide the following supporting tools:

a).Transformer

b) Push-out lining system

c) Loading cell system

d).Charging system for solid material

e).Deslag system

f). Emergency diesel generator

4.As a tin melting furnace manufacturer,how long is the delivery time? If I want to customize the equipment, how long does it takes?

We can provide customized service for our coustomers. It usually takes 30-60 days depending on the specifications of the customer equipment.

5.Does this tin melting furnace comply with international electrical safety standards?

It depends on the specific electric furnace and the international electrical safety standards in question. It is best to consult the manufacturer of the electric furnace to determine if it complies with the relevant standards.

6.What material is the heating element of this electric furnace usually made of?

The heating element of an electric furnace is typically made of a nickel-chromium alloy, such as Nichrome.

7.As a tin melting furnace manufacturer,how can we guarantee quality?

Ensure the excellent performance and accuracy of our product line by controlling, inspecting and improving the optimized quality mechanism of our products.All our products have undergone various quality tests to ensure that they comply with the specifications and standards stipulated by the industry.

8.Is the tin melting furnace suitable for commercial use?

Yes, electric furnaces are suitable for commercial use. They are often used in commercial buildings to provide heating and cooling.

9.What are the advantages of electric furnace compared to traditional gas or oil furnaces?

Our tin melting furnace products undergo strict quality control to ensure customer satisfaction.

1. Lower Operating Costs: Electric furnaces are more energy efficient than traditional gas or oil furnaces, resulting in lower monthly energy bills.

2. Cleaner Burning: Electric furnaces do not produce any emissions, making them a much cleaner burning option than traditional gas or oil furnaces.

3. Quieter Operation: Electric furnaces are much quieter than traditional gas or oil furnaces, making them a great option for those who want a quieter home.

4. Longer Lifespan: Electric furnaces typically have a longer lifespan than traditional gas or oil furnaces, meaning you won’t have to replace them as often.

5. Easier Maintenance: Electric furnaces require less maintenance than traditional gas or oil furnaces, making them a great option for those who don’t want to spend a lot of time and money on maintenance.

10.As a tin melting furnace manufacturer,how is the package of the goods ? Delivery methods?

According to the specific conditions of the equipment, it is packed in a fumigation-free wooden box, PVC wrapping film and plastic woven cloth. Sea shipping and railway transport for whole set of the equipment as well as Express according to customer requirements, find the most suitable way.

11.Does the tin melting furnace have dust prevention and filtration functions?

Yes, many electric furnaces come with dust prevention and filtration functions. These features help to reduce the amount of dust and other airborne particles that can be released into the air. Some models also come with air purification systems that can help to reduce the amount of allergens and other pollutants in the air.

12.Does this tin melting furnace meet environmental standards?

It depends on the specific model and age of the electric furnace. In general, electric furnaces manufactured after 1992 must meet certain environmental standards, such as those set by the Environmental Protection Agency (EPA). It is best to contact the manufacturer of the electric furnace to determine if it meets the necessary standards.

13.How much space can this tin melting furnace provide enough heat?

The amount of space an tin melting furnace can provide enough heat for depends on the size and power of the furnace. Generally, a furnace with a capacity of 40,000 BTU can provide enough heat for a space of up to 1,500 square feet.

14.How does an tin melting furnace utilize resistance to generate heat?

An tin melting furnace utilizes resistance to generate heat by passing an electric current through a heating element, usually made of metal. The resistance of the metal causes it to heat up, and the heat is then transferred to the air in the furnace.

15.Is there a remote monitoring or alarm system for the tin melting furnace?

Yes, there are several remote monitoring and alarm systems available for electric furnaces. These systems can be used to monitor the temperature, humidity, and other conditions in the furnace, as well as alert you to any potential problems.

Tags:electric forge furnace,vacuum assisted evacuation furnace,electric furnace short cycling,heat pump and electric furnace