Welcome to Shandong Kehua Intellient Equipment Co.,Ltd. Our company is located in Weifang City, Shandong Province, with convenient transportation. As a heating equipment supplier with over 20 years of experience, we have hired numerous experts and engineers in the industry, dedicated to technological innovation and research and development of fusion heating and treatment equipment. Our products have been exported to Africa,Europe,Oceania,Afghanistan,Gabon,Chad,Qatar,Cocos (Keeling) Islands and other regions and countries.

Nowadays, we are engaged in the design and manufacturing of tube furnaces,smelting furnaces,induction furnace,elevator furnaces,melting furnace,heat treatment furnace,electric furnaces,industrial room furnaces,water-cooled pumps. We provide extensive research and development, and we also welcome OEM and ODM orders. Our high-quality engineers, technicians, and factory personnel will work with you to produce cost-effective and high-quality products to meet your needs. All of our products have undergone various quality tests to ensure they comply with industry regulations and standards. In addition, our quality control experts closely monitor the entire process from production to scheduling to provide quality ranges approved by certification standards such as ISO 9001 and ISO 14001:2015.

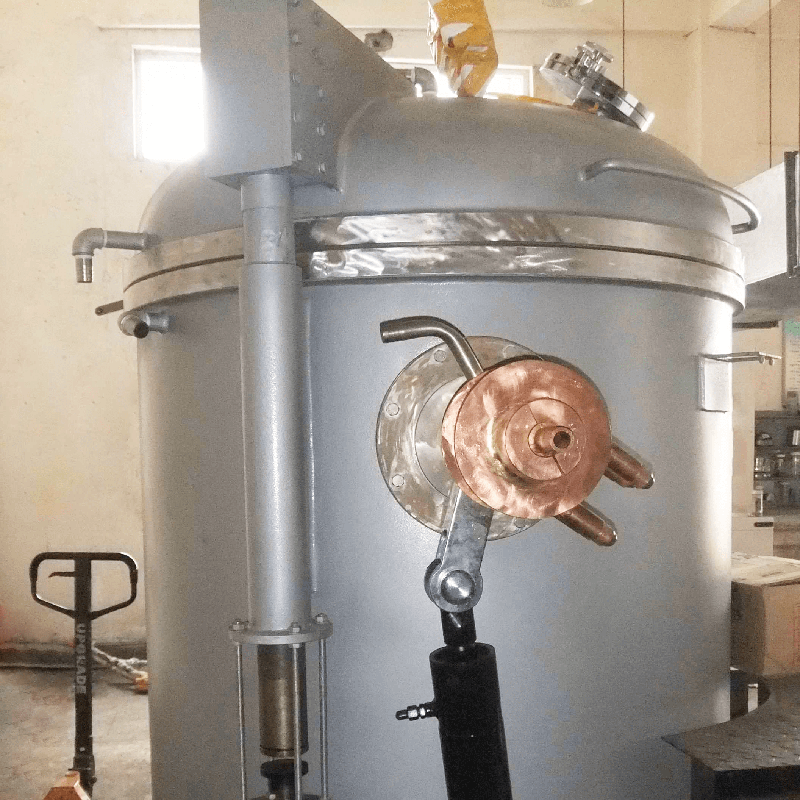

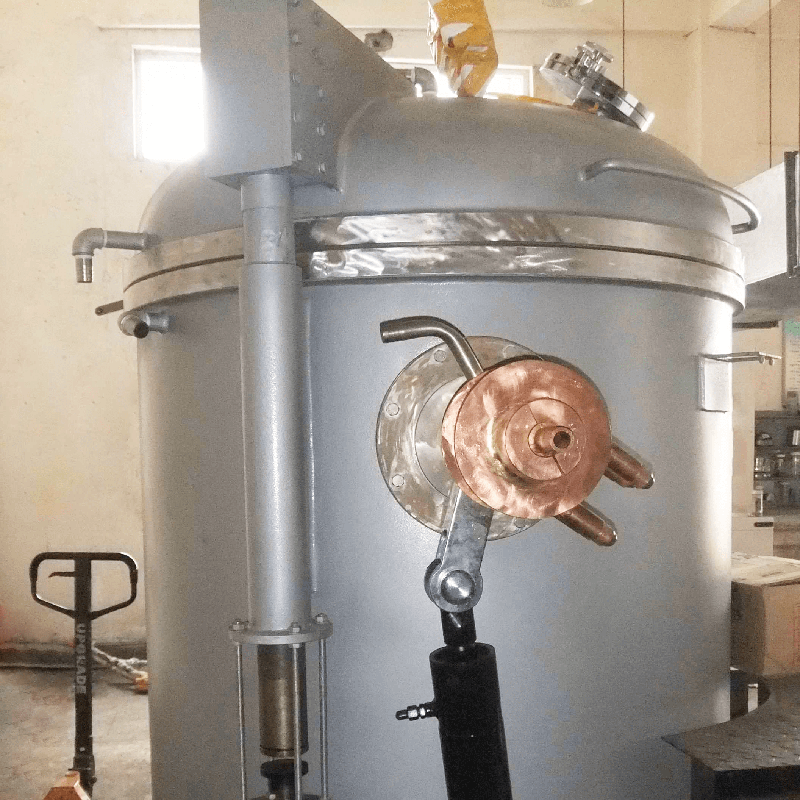

| # | mini vacuum furnace Parameter | Information

|

| 1 | Product catalog: | Induction Furnace

|

| 2 | Material:

| Stainless steel, heat-resistant steel, refractory materials, etc

|

| 3 | Usage: | Heat treated glass,Manufacturing alloys,Manufacturing of sealing materials,Casting and forging,Melting scrap metal |

| 4 | Color:

| Customized

|

| 5 | Place of Origin:

| Weifang, Shandong, China

|

| 6 | Packing:

| Standard export packing

|

| 7 | Marketing Type: | Ordinary Product

|

| 8 | Quality Guarantee:

| 1 year

|

| 9 | Brand Name:

| Kehua

|

| 10 | Export region:

| Europe,Asia,Oceania

Portugal,Angola,Glorioso Islands,Saint Lucia,Grenada

|

| 11 | Order Lead Time:

| 30-40 days after the order is confirmed

|

| 12 | Packing size(cm):

| 257*237*223 Specific consultation with us

|

| 13 | OEM/ODM:

| Acceptale

|

| 14 | MOQ: | 1 set |

| 15 | Certificate: | ISO90001 |

| 16 | Weight(kg):

| 2658

|

| 17 | Key Selling Points:

| Competitive Price

|

| 18 | After-sales service:

| Provide assembly and commissioning, training and eliminate risks, one stop solution to your worries

|

| 19 | Video outgoing-inspection

| Provided

|

| 20 | Voltage

| 110V/220V/38V |

Please note: This table is for reference only, please consult us for specific information.

The product has characteristics such as high safety, durability, high efficiency, and convenient maintenance.The power cabinet is also equipped with a smelting manager. PLC and man-machine interface constitute a convenient operation of the smelting manager, the functions include: system status display,automatic furnace start,fault information display and storage,cold furnace start,fault diagnosis, etc.

There are many different types of mini vacuum furnace, and their working methods often vary slightly. These furnaces have three to six resistance heating elements, each ranging from 3.5 to 7 kW. The working principle of these heating elements is very similar to the heating elements in a toaster. Charged particles move through metal wires, generating heat. The heating element is made of long wires, which are wound into coils and installed in the furnace.

12 months warranty once the equipment is ready for production.Kehua provide warranty parts free of charge within 12 months or at market competitive price when out of expiration. Kehua have been realizing the importance of feedback from users and providing technical and service supports from the born day, which is also driving us to step together with metal casting, forging and heat treatment industry.

mini vacuum furnace---FAQs Guide

1.As a mini vacuum furnace manufacturer,how can we guarantee quality?

Ensure the excellent performance and accuracy of our product line by controlling, inspecting and improving the optimized quality mechanism of our products.All our products have undergone various quality tests to ensure that they comply with the specifications and standards stipulated by the industry.

2.What are the after-sales services available for mini vacuum furnace?

Provide assembly and commissioning, training and eliminate risks, one stop solution to your worries. Quality Guarantee: 1 year. During the warranty period, accessories are provided free of charge; after the warranty period, accessories are provided in time at a preferential price and guide installation and commissioning.

3.How sturdy and durable are the heating elements of an mini vacuum furnace?

Electric furnaces are designed to be very durable and long-lasting. The heating elements are typically made of high-grade materials such as stainless steel or nickel-chromium alloys, which are designed to withstand high temperatures and resist corrosion. The heating elements are also designed to be shock-resistant and able to withstand vibrations. With proper maintenance and care, electric furnaces can last for many years.

4.Does this mini vacuum furnace comply with international electrical safety standards?

It depends on the specific electric furnace and the international electrical safety standards in question. It is best to consult the manufacturer of the electric furnace to determine if it complies with the relevant standards.

5.Can the mini vacuum furnace be adjusted at different temperatures?

Yes, most mini vacuum furnace can be adjusted to different temperatures. The exact method of adjustment will depend on the specific model of furnace.

6.Does the mini vacuum furnace have an overheating protection mechanism?

Yes, most mini vacuum furnace have an overheating protection mechanism. This typically includes a high-limit switch that will shut off the furnace if the temperature gets too high.

7.What different industrial fields can electric furnace be applied to?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services.

Electric furnaces can be used in a variety of industrial fields, including:

1. Metalworking: Electric furnaces are used to melt and alloy metals, such as steel, aluminum, and copper.

2. Ceramics: Electric furnaces are used to fire ceramic products, such as pottery and tiles.

3. Glassmaking: Electric furnaces are used to melt and shape glass products.

4. Refractory: Electric furnaces are used to produce refractory materials, such as bricks and insulation.

5. Petrochemical: Electric furnaces are used to refine and process petroleum products.

6. Heat Treatment: Electric furnaces are used to heat treat metals and alloys.

7. Food Processing: Electric furnaces are used to dry and process food products.

8.What is the temperature range of this mini vacuum furnace?

The temperature range of an electric furnace typically ranges from 50°F to 90°F.

9.As a mini vacuum furnace manufacturer,how long is the delivery time? If I want to customize the equipment, how long does it takes?

We can provide customized service for our coustomers. It usually takes 30-60 days depending on the specifications of the customer equipment.

10.Does the mini vacuum furnace have a fast heating function?

Some mini vacuum furnace do have a fast heating function, but this is not a standard feature on all models. It is best to check with the manufacturer to see if the specific model you are considering has this feature.

11.What are the safety features of electric furnace?

Being one of the top mini vacuum furnace manufacturers in China, We attach great importance to this detail.

1. Overheat Protection: Electric furnaces are equipped with an overheat protection system that will shut off the furnace if it gets too hot.

2. Flame Sensor: Electric furnaces are equipped with a flame sensor that will shut off the furnace if it detects a flame.

3. Carbon Monoxide Detector: Electric furnaces are equipped with a carbon monoxide detector that will shut off the furnace if it detects dangerous levels of carbon monoxide.

4. Ground Fault Circuit Interrupter: Electric furnaces are equipped with a ground fault circuit interrupter (GFCI) that will shut off the furnace if it detects an electrical fault.

5. Pressure Switch: Electric furnaces are equipped with a pressure switch that will shut off the furnace if it detects a pressure drop.

6. Flame Rollout Switch: Electric furnaces are equipped with a flame rollout switch that will shut off the furnace if it detects a flame rolling out of the burner.

12.What accessories are included in the packaging of mini vacuum furnace products?

The accessories included in the packaging of electric furnace products typically include a furnace, a thermostat, a blower, a filter, a vent pipe, a vent cap, a wiring harness, and installation instructions.

13.Is the performance of the mini vacuum furnace affected by temperature changes?

Yes, the performance of an mini vacuum furnace can be affected by temperature changes. Temperature changes can affect the efficiency of the furnace, as well as the amount of heat produced. Additionally, temperature changes can cause the furnace to overheat, leading to potential safety hazards.

Tags:wattage of electric furnace,90000 btu electric furnace,electric garage furnace heater,mtap electric furnace,vacuum degassing furnace,heat treatment vacuum furnace