Kehua Intellient Equipment Co.,Ltd is a leading manufacturer of laboratory furnaces, industrial furnaces, smelting furnaces, heating elements, and related accessories. As a manufacturer with over 20 years of experience in thermal engineering, we offer a wide and in-depth range of furnaces worldwide. Satisfied customers from multiple countries have demonstrated our commitment to excellent design, quality, and cost-effectiveness. For example, countries and regions such as Europe,Asia,America and Angola,Niue,Ukraine,Ireland,Greece.

Our products mainly include: heat treatment furnace,induction furnace,water-cooled pumps,high-temperature furnaces,smelting furnaces,tube furnaces,industrial room furnaces,elevator furnaces,melting furnace, etc. Our company provides heating and treatment equipment for laboratories, domestic and foreign universities, research institutes, factories, as well as industries such as petrochemicals, smelting, casting, mechanical manufacturing, and military industry. All of our products have undergone various quality tests to ensure they comply with industry regulations and standards. In addition, our quality control experts closely monitor the entire process from production to scheduling to provide quality ranges approved by certification standards such as ISO 9001 and ISO 14001:2015.

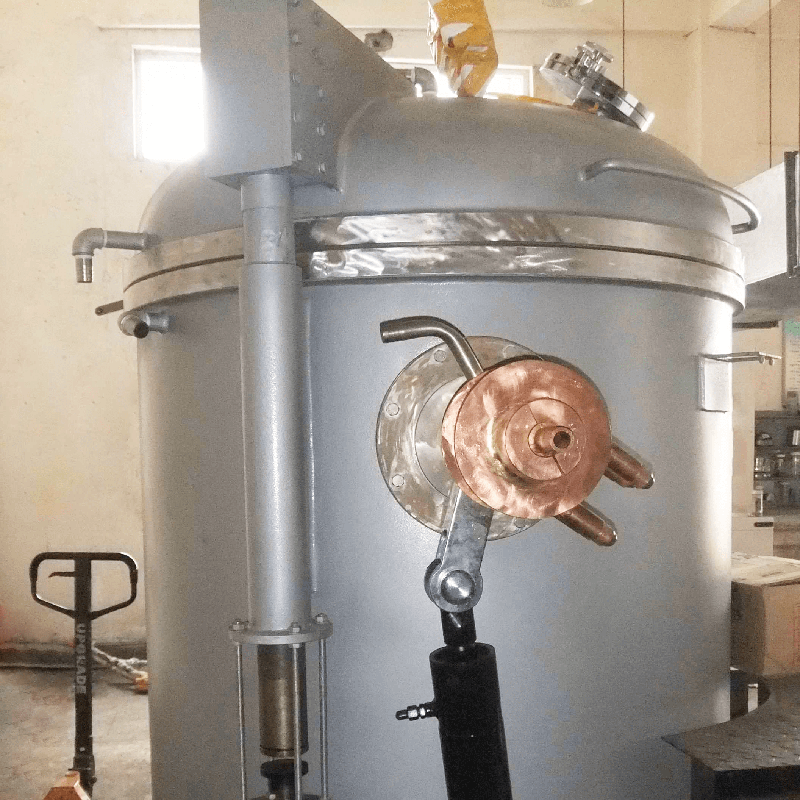

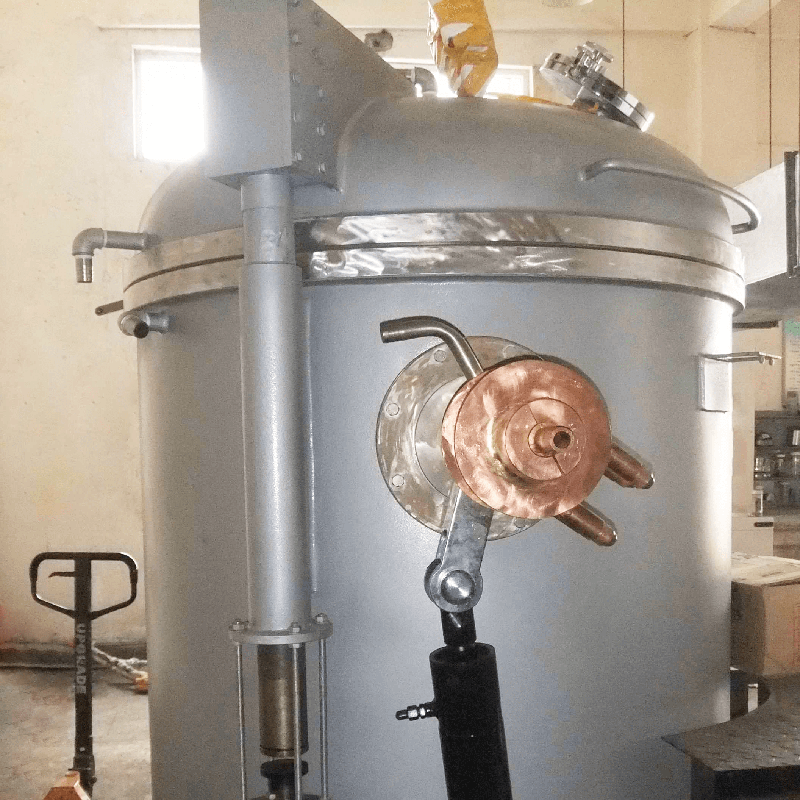

| # | industrial metal melting furnace Parameter | Information

|

| 1 | Product catalog: | Induction Furnace

|

| 2 | Material:

| Stainless steel, heat-resistant steel, refractory materials, etc

|

| 3 | Usage: | Heat treated glass,Manufacturing alloys,Biomedical field,Cupola metal,Manufacturing of sealing materials |

| 4 | Color:

| Customized

|

| 5 | Place of Origin:

| Shandong,China

|

| 6 | Packing:

| Standard export packing

|

| 7 | Marketing Type: | Ordinary Product

|

| 8 | Quality Guarantee:

| 1 year

|

| 9 | Brand Name:

| Kehua

|

| 10 | Export region:

| America,Europe,Africa

Belarus,Antigua and Barbuda,Saint Pierre and Miquelon,Navassa Island,Kuwait

|

| 11 | Order Lead Time:

| 30-40 days after the order is confirmed

|

| 12 | Packing size(cm):

| 268*159*160 Specific consultation with us

|

| 13 | OEM/ODM:

| Acceptale

|

| 14 | MOQ: | 1 set |

| 15 | Certificate: | ISO90001 |

| 16 | Weight(kg):

| 2474

|

| 17 | Key Selling Points:

| Easy to Operate

|

| 18 | After-sales service:

| Provide assembly and commissioning, training and eliminate risks, one stop solution to your worries

|

| 19 | Video outgoing-inspection

| Provided

|

| 20 | Voltage

| 110V/220V/38V |

Please note: This table is for reference only, please consult us for specific information.

In 2023, Kehua provided customer with a 1 tows 5 solutions by a 5 Ton iron scrap melting electric furnaces. This program includes a series resonant five-output power cabinet and five furnace bodies. The advantage is that 5 furnaces can work at the same time, with 3 melting and 2 for temperature holding, by this connection, we saved the room space for power supply cabinet, and also got a energy-reducing compared with parallel resonance or general series resonance.

12 months warranty once the equipment is ready for production.Kehua provide warranty parts free of charge within 12 months or at market competitive price when out of expiration. Kehua have been realizing the importance of feedback from users and providing technical and service supports from the born day, which is also driving us to step together with metal casting, forging and heat treatment industry.

industrial metal melting furnace---FAQs Guide

1.What is the price of an industrial metal melting furnace?

The price of an industrial metal melting furnace can vary greatly depending on the size, type, and features of the furnace. Prices can range from around $1,000 to $5,000 or more.

2.As a industrial metal melting furnace manufacturer,how is the package of the goods ? Delivery methods?

According to the specific conditions of the equipment, it is packed in a fumigation-free wooden box, PVC wrapping film and plastic woven cloth. Sea shipping and railway transport for whole set of the equipment as well as Express according to customer requirements, find the most suitable way.

3.How sturdy and durable are the heating elements of an industrial metal melting furnace?

Electric furnaces are designed to be very durable and long-lasting. The heating elements are typically made of high-grade materials such as stainless steel or nickel-chromium alloys, which are designed to withstand high temperatures and resist corrosion. The heating elements are also designed to be shock-resistant and able to withstand vibrations. With proper maintenance and care, electric furnaces can last for many years.

4.Do industrial metal melting furnace have energy-saving characteristics?

Yes, industrial metal melting furnace can have energy-saving characteristics. Many electric furnaces are designed with energy-saving features such as variable speed blowers, two-stage heating, and programmable thermostats. These features can help reduce energy consumption and lower energy bills.

5.Does this industrial metal melting furnace have a timing switch function?

It depends on the specific model of industrial metal melting furnace. Some models may have a timing switch function, while others may not. It is best to consult the manufacturer's manual or contact the manufacturer directly to determine if the specific model of electric furnace has a timing switch function.

6.Is there a remote monitoring or alarm system for the industrial metal melting furnace?

Yes, there are several remote monitoring and alarm systems available for electric furnaces. These systems can be used to monitor the temperature, humidity, and other conditions in the furnace, as well as alert you to any potential problems.

7.What different industrial fields can electric furnace be applied to?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services.

Electric furnaces can be used in a variety of industrial fields, including:

1. Metalworking: Electric furnaces are used to melt and alloy metals, such as steel, aluminum, and copper.

2. Ceramics: Electric furnaces are used to fire ceramic products, such as pottery and tiles.

3. Glassmaking: Electric furnaces are used to melt and shape glass products.

4. Refractory: Electric furnaces are used to produce refractory materials, such as bricks and insulation.

5. Petrochemical: Electric furnaces are used to refine and process petroleum products.

6. Heat Treatment: Electric furnaces are used to heat treat metals and alloys.

7. Food Processing: Electric furnaces are used to dry and process food products.

8.What is the general weight of an industrial metal melting furnace?

The weight of an industrial metal melting furnace can vary greatly depending on the size and model. Generally, electric furnaces range in weight from about 100 to 500 pounds.

9.Is there an option to extend the warranty for industrial metal melting furnace?

Yes, many industrial metal melting furnace manufacturers offer extended warranties that can be purchased for an additional cost. These extended warranties typically cover parts and labor for a longer period of time than the standard warranty. Contact the manufacturer of your electric furnace for more information.

10.As a industrial metal melting furnace manufacturer,do you accept OEM?

Yes, we accept OEM, it would be better if you can provide detailed drawings or pictures.

11.Does this industrial metal melting furnace have the function of automatically adjusting power?

It depends on the specific model of industrial metal melting furnace. Some models may have this feature, while others may not.

12.How long is the lifespan of this industrial metal melting furnace?

The lifespan of an industrial metal melting furnace can vary depending on the make and model, but typically they last between 15 and 20 years.

13.What accessories are included in the packaging of industrial metal melting furnace products?

The accessories included in the packaging of electric furnace products typically include a furnace, a thermostat, a blower, a filter, a vent pipe, a vent cap, a wiring harness, and installation instructions.

14.Do industrial metal melting furnace have different appearances or colors?

No, electric furnaces typically have a standard appearance and color.

15.Does the industrial metal melting furnace have an overheating protection mechanism?

Yes, most industrial metal melting furnace have an overheating protection mechanism. This typically includes a high-limit switch that will shut off the furnace if the temperature gets too high.

16.As a industrial metal melting furnace manufacturer,how can we guarantee quality?

Ensure the excellent performance and accuracy of our product line by controlling, inspecting and improving the optimized quality mechanism of our products.All our products have undergone various quality tests to ensure that they comply with the specifications and standards stipulated by the industry.

Tags:lifespan of electric furnace,electric glass blowing furnace,vacuum melting furnace,vacuum hardening furnace