Kehua Intellient Equipment, located in the picturesque city of Weifang, Shandong Province. With superior geographical location and convenient transportation network, it is a production-oriented enterprise that integrates scientific research, production, sales, and service. Our products have a wide variety, such as vacuum furnaces,elevator furnaces,industrial room furnaces,intelligent mobile bottom furnaces,water-cooled pumps,heat treatment furnace,melting furnace,electric furnaces,induction furnace, etc., with excellent quality, reasonable prices, fashionable designs, and are widely used in industries such as construction, metal casting and forging, heat treated glass, semiconductor material production, and ceramic manufacturing. Our products have gained widespread recognition and trust from users, and have been exported to regions and countries such as Europe,Africa,Oceania and Bosnia and Herzegovina,San Marino,Juan de Nova Island,Czech Republic,Central African Republic,Venezuela.

We have modern infrastructure and professional personnel who can help us develop testing equipment based on the specific requirements of our customers. By controlling, inspecting, and improving the optimization quality mechanism of our products, we ensure the excellent performance and accuracy of our product line. The company has passed ISO9001 quality certification and CE certification.

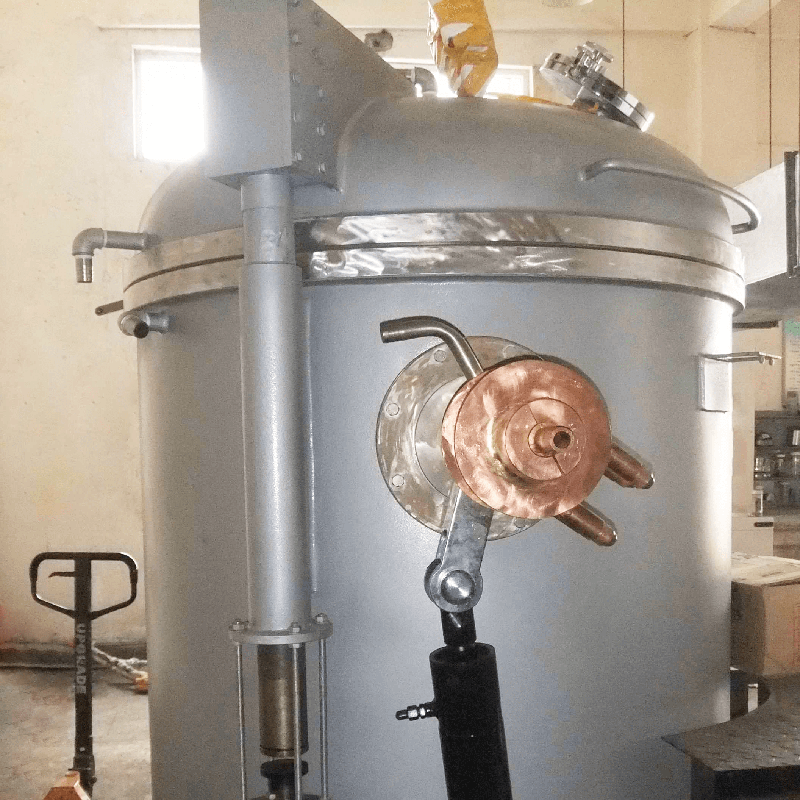

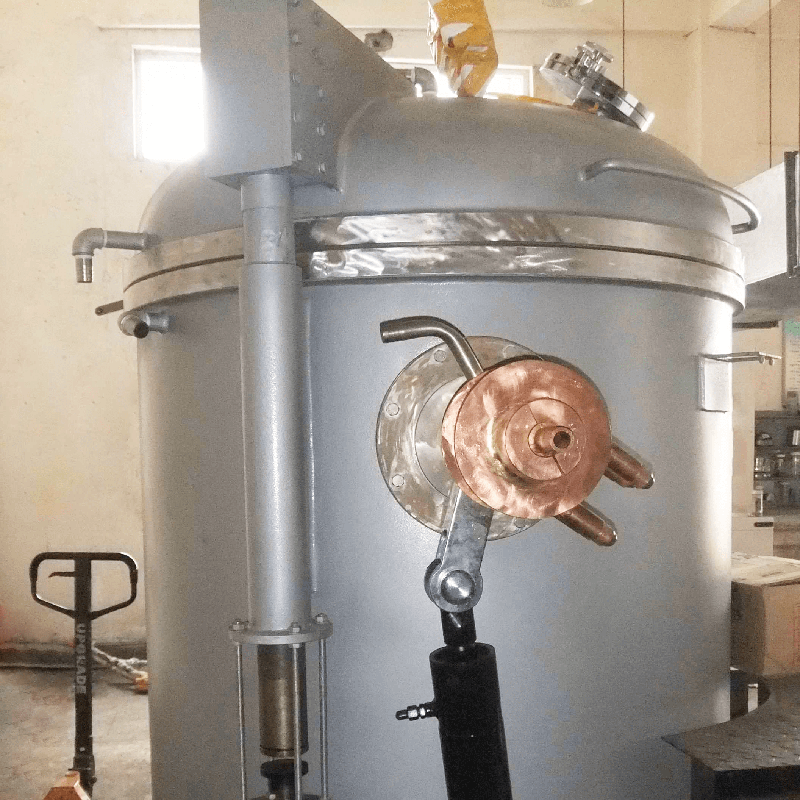

| Product name | induction furnace for casting |

| Place of Origin | China |

| Machinery Test Report | Provided |

Product Type

| Induction Furnace

|

| Warranty of core components | 1Year

|

Condition

| New |

Core Components

| PLC, Engine, Gear

|

Packing Size(cm)

| 497*170*231 Specific consultation with us

|

| Brand Name | Kehua

|

Export region

| Europe,Asia,Oceania Italy,Kenya,Burundi,Marshall Islands,Mali

|

Weight(kg)

| 4907

|

Power (kW)

| It depends

|

Key Selling Points

| Automatic

|

Voltage

| 110V/220V/380V

|

After Warranty Service

| Video technical support

|

After-sales Service

| Provided Online Support

|

Video outgoing-inspection

| Provided

|

Packaging Details

| Polyfoam filled, Wooden box outside

|

Supply Ability

| 20-100 Set/Sets per Month (See specific model products) |

Lead time (days)

| 40 (To be negotiated)

|

Please note: This table is for reference only, please consult us for specific information.

An electric furnace is a heating device that operates by converting electrical energy into heat energy. It is commonly used for industrial and residential applications, and it replaces traditional furnaces that use natural gas or oil.induction furnace for casting has a simple structure, convenient maintenance, low energy consumption, and significant energy-saving effects.

One of the major advantages of electric furnaces is their efficiency. Unlike traditional furnaces that lose a significant amount of heat through exhaust gases and mechanical systems, an electric furnace converts almost all of the electrical energy it receives into heat. This makes electric furnaces more energy-efficient and cost-effective in the long run.Another advantage of electric furnaces is their clean operation. Since there are no combustion byproducts, there is no need for a chimney or exhaust system, making it a cleaner and safer option for indoor use. Additionally, electric furnaces do not produce carbon monoxide, making them a popular choice for homes or buildings with poor ventilation.

12 months warranty once the equipment is ready for production.Kehua provide warranty parts free of charge within 12 months or at market competitive price when out of expiration. Kehua have been realizing the importance of feedback from users and providing technical and service supports from the born day, which is also driving us to step together with metal casting, forging and heat treatment industry.

induction furnace for casting---FAQs Guide

1.Does the induction furnace for casting provide multiple heating modes or settings?

Yes, most electric furnaces provide multiple heating modes or settings. These settings can include low, medium, and high heat settings, as well as fan-only settings. Some electric furnaces also offer additional features such as programmable thermostats, energy-saving settings, and zone control.

2.How much space can this induction furnace for casting provide enough heat?

The amount of space an induction furnace for casting can provide enough heat for depends on the size and power of the furnace. Generally, a furnace with a capacity of 40,000 BTU can provide enough heat for a space of up to 1,500 square feet.

3.Does this induction furnace for casting have the characteristic of silent operation?

No, induction furnace for casting do not typically have the characteristic of silent operation.

4.What is the heating efficiency of the induction furnace for casting?

The heating efficiency of an electric furnace depends on the type of furnace and the efficiency rating of the furnace. Generally, electric furnaces have an efficiency rating of 80-95%, meaning that 80-95% of the energy used to power the furnace is converted into heat.

5.What is the starting and stopping process of an induction furnace for casting?

The starting process of an induction furnace for casting involves turning on the power switch, setting the thermostat, and allowing the furnace to heat up. The stopping process involves turning off the power switch and allowing the furnace to cool down.

6.What accessories are included in the packaging of induction furnace for casting products?

The accessories included in the packaging of electric furnace products typically include a furnace, a thermostat, a blower, a filter, a vent pipe, a vent cap, a wiring harness, and installation instructions.

7.About induction furnace for casting,how about your company's certification?

The company has passed ISO9001 quality certification and CE certification.

8.Does the induction furnace for casting have an overheating protection mechanism?

Yes, most induction furnace for casting have an overheating protection mechanism. This typically includes a high-limit switch that will shut off the furnace if the temperature gets too high.

9.What is the control method for induction furnace for casting?

The most common control method for induction furnace for casting is a thermostat. The thermostat is used to regulate the temperature of the furnace by turning the heating elements on and off as needed. Other control methods include using a timer, a programmable thermostat, or a remote control.

10.What is the general weight of an induction furnace for casting?

The weight of an induction furnace for casting can vary greatly depending on the size and model. Generally, electric furnaces range in weight from about 100 to 500 pounds.

11.Can the induction furnace for casting be controlled through a remote control or mobile app?

Yes, some induction furnace for casting can be controlled through a remote control or mobile app. However, this depends on the specific model of furnace and the features it offers.

12.As a induction furnace for casting manufacturer,how long is the delivery time? If I want to customize the equipment, how long does it takes?

We can provide customized service for our coustomers. It usually takes 30-60 days depending on the specifications of the customer equipment.

13.How does an induction furnace for casting utilize resistance to generate heat?

An induction furnace for casting utilizes resistance to generate heat by passing an electric current through a heating element, usually made of metal. The resistance of the metal causes it to heat up, and the heat is then transferred to the air in the furnace.

Tags:electric furnace carrier,onsite heat treatment furnace,electra heat treat furnace,electric cupellation furnace,discount electric furnace,magnetic induction furnace,induction furnace for brass melting