Kehua Intellient Equipment, located in Shandong Province, integrates research and development, production, sales, and after-sales service. Our products include melting furnace,electric furnaces,water-cooled pumps,vacuum furnaces,industrial room furnaces,high-temperature furnaces,heat treatment furnace,induction furnace,tube furnaces, etc. We are a professional supplier and service provider of electric furnace equipment. Our company provides heating and treatment equipment for laboratories, domestic and foreign universities, research institutes, factories, as well as industries such as petrochemicals, smelting, casting, mechanical manufacturing, and military industry. And it has passed ISO9001 quality certification and CE certification.

At the same time, professional after-sales engineers and maintenance technicians are equipped to provide assembly and debugging, training, and risk elimination, providing a one-stop solution to your concerns and ensuring fast and efficient after-sales service. Additionally, the quality is guaranteed for one year. During the warranty period, free accessories are provided. Our products have been exported to more than ten countries and regions such as Europe,Oceania,Asia and Kenya,Portugal,Isle of Man,South Africa,United States of America,Gambia, and have received high recognition from customers.

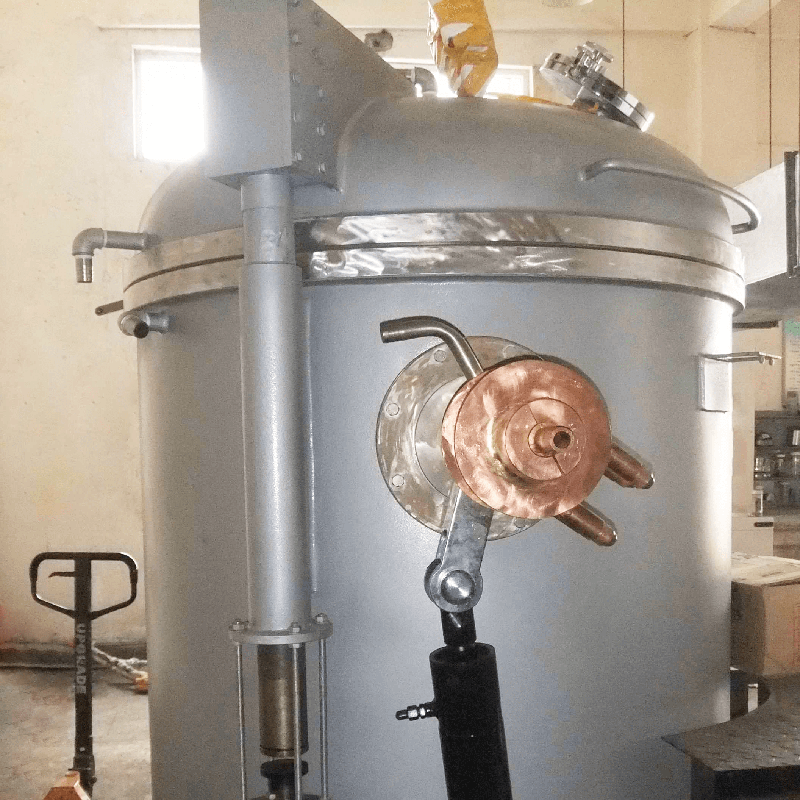

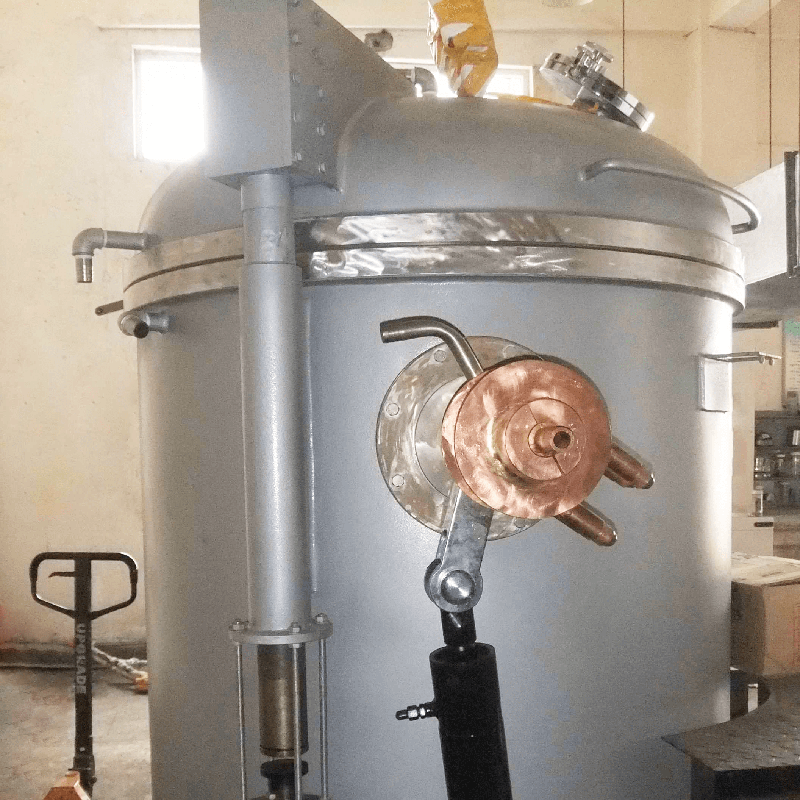

| Product name | induction annealing furnace |

| Place of Origin | Weifang, Shandong |

| Machinery Test Report | Provided |

Product Type

| Induction Furnace

|

| Warranty of core components | 12 Month

|

Condition

| New |

Core Components

| Furance,Vacuum Pump

|

Packing Size(cm)

| 398*237*163 Specific consultation with us

|

| Brand Name | Kehua

|

Export region

| Oceania,America,Asia Ireland,Northern Mariana Islands,Croatia,Libya,Puerto Rico

|

Weight(kg)

| 4777

|

Power (kW)

| It depends

|

Key Selling Points

| Accurate temperature control

|

Voltage

| 110V/220V/380V

|

After Warranty Service

| Video technical support

|

After-sales Service

| Video technical support, Online support

|

MOQ

| 1 set

|

Packaging Details

| Polyfoam filled, Wooden box outside

|

Supply Ability

| 10-20 Set/Sets per Month (See specific model products) |

Lead time (days)

| 30-40 (To be negotiated)

|

Please note: This table is for reference only, please consult us for specific information.

The product has characteristics such as high safety, durability, high efficiency, and convenient maintenance.The power cabinet is also equipped with a smelting manager. PLC and man-machine interface constitute a convenient operation of the smelting manager, the functions include: automatic furnace start,fault diagnosis,system status display,operation information display,fault information display and storage, etc.

There are many different types of induction annealing furnace, and their working methods often vary slightly. These furnaces have three to six resistance heating elements, each ranging from 3.5 to 7 kW. The working principle of these heating elements is very similar to the heating elements in a toaster. Charged particles move through metal wires, generating heat. The heating element is made of long wires, which are wound into coils and installed in the furnace.

12 months warranty once the equipment is ready for production.Kehua provide warranty parts free of charge within 12 months or at market competitive price when out of expiration. Kehua have been realizing the importance of feedback from users and providing technical and service supports from the born day, which is also driving us to step together with metal casting, forging and heat treatment industry.

induction annealing furnace---FAQs Guide

1.Does this induction annealing furnace meet environmental standards?

It depends on the specific model and age of the electric furnace. In general, electric furnaces manufactured after 1992 must meet certain environmental standards, such as those set by the Environmental Protection Agency (EPA). It is best to contact the manufacturer of the electric furnace to determine if it meets the necessary standards.

2.About induction annealing furnace,how about your company's certification?

The company has passed ISO9001 quality certification and CE certification.

3.How sturdy and durable are the heating elements of an induction annealing furnace?

Electric furnaces are designed to be very durable and long-lasting. The heating elements are typically made of high-grade materials such as stainless steel or nickel-chromium alloys, which are designed to withstand high temperatures and resist corrosion. The heating elements are also designed to be shock-resistant and able to withstand vibrations. With proper maintenance and care, electric furnaces can last for many years.

4.What is the control method for induction annealing furnace?

The most common control method for induction annealing furnace is a thermostat. The thermostat is used to regulate the temperature of the furnace by turning the heating elements on and off as needed. Other control methods include using a timer, a programmable thermostat, or a remote control.

5.What are the safety features of electric furnace?

Being one of the top induction annealing furnace manufacturers in China, We attach great importance to this detail.

1. Overheat Protection: Electric furnaces are equipped with an overheat protection system that will shut off the furnace if it gets too hot.

2. Flame Sensor: Electric furnaces are equipped with a flame sensor that will shut off the furnace if it detects a flame.

3. Carbon Monoxide Detector: Electric furnaces are equipped with a carbon monoxide detector that will shut off the furnace if it detects dangerous levels of carbon monoxide.

4. Ground Fault Circuit Interrupter: Electric furnaces are equipped with a ground fault circuit interrupter (GFCI) that will shut off the furnace if it detects an electrical fault.

5. Pressure Switch: Electric furnaces are equipped with a pressure switch that will shut off the furnace if it detects a pressure drop.

6. Flame Rollout Switch: Electric furnaces are equipped with a flame rollout switch that will shut off the furnace if it detects a flame rolling out of the burner.

6.Do induction annealing furnace have different appearances or colors?

No, electric furnaces typically have a standard appearance and color.

7.What accessories are included in the packaging of induction annealing furnace products?

The accessories included in the packaging of electric furnace products typically include a furnace, a thermostat, a blower, a filter, a vent pipe, a vent cap, a wiring harness, and installation instructions.

8.As a induction annealing furnace manufacturer,how is the package of the goods ? Delivery methods?

According to the specific conditions of the equipment, it is packed in a fumigation-free wooden box, PVC wrapping film and plastic woven cloth. Sea shipping and railway transport for whole set of the equipment as well as Express according to customer requirements, find the most suitable way.

9.Does the induction annealing furnace have a fast heating function?

Some induction annealing furnace do have a fast heating function, but this is not a standard feature on all models. It is best to check with the manufacturer to see if the specific model you are considering has this feature.

10.What are the advantages of electric furnace compared to traditional gas or oil furnaces?

Our induction annealing furnace products undergo strict quality control to ensure customer satisfaction.

1. Lower Operating Costs: Electric furnaces are more energy efficient than traditional gas or oil furnaces, resulting in lower monthly energy bills.

2. Cleaner Burning: Electric furnaces do not produce any emissions, making them a much cleaner burning option than traditional gas or oil furnaces.

3. Quieter Operation: Electric furnaces are much quieter than traditional gas or oil furnaces, making them a great option for those who want a quieter home.

4. Longer Lifespan: Electric furnaces typically have a longer lifespan than traditional gas or oil furnaces, meaning you won’t have to replace them as often.

5. Easier Maintenance: Electric furnaces require less maintenance than traditional gas or oil furnaces, making them a great option for those who don’t want to spend a lot of time and money on maintenance.

11.What different industrial fields can electric furnace be applied to?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services.

Electric furnaces can be used in a variety of industrial fields, including:

1. Metalworking: Electric furnaces are used to melt and alloy metals, such as steel, aluminum, and copper.

2. Ceramics: Electric furnaces are used to fire ceramic products, such as pottery and tiles.

3. Glassmaking: Electric furnaces are used to melt and shape glass products.

4. Refractory: Electric furnaces are used to produce refractory materials, such as bricks and insulation.

5. Petrochemical: Electric furnaces are used to refine and process petroleum products.

6. Heat Treatment: Electric furnaces are used to heat treat metals and alloys.

7. Food Processing: Electric furnaces are used to dry and process food products.

12.Is there an option to extend the warranty for induction annealing furnace?

Yes, many induction annealing furnace manufacturers offer extended warranties that can be purchased for an additional cost. These extended warranties typically cover parts and labor for a longer period of time than the standard warranty. Contact the manufacturer of your electric furnace for more information.

13.What is the starting and stopping process of an induction annealing furnace?

The starting process of an induction annealing furnace involves turning on the power switch, setting the thermostat, and allowing the furnace to heat up. The stopping process involves turning off the power switch and allowing the furnace to cool down.

Tags:pillar induction furnace,intertherm furnace electric,electric furnace fuse,electric crematorium furnace,eb15b central electric furnace,electric wall furnaces,electric arc furnace dust