Shandong Kehua Intellient Equipment is a professional manufacturer for Medium frequency induction melting and heating equipmets, which is located in Weifang City, Shandong China, regards “quality as life , integrity as fundamental”, always implements customer service as the center , takes advanced quality management system , advanced mature technical force and perfect after-sales service system as its guarantee, and provides customers with more and more good products, technologies and services.

Our products mainly include:high-temperature furnaces,vacuum furnaces,smelting furnaces,intelligent mobile bottom furnaces,heat treatment furnace,induction furnace,water-cooled pumps,elevator furnaces,melting furnace,etc. Our company provides heating and treatment equipment for laboratories, domestic and foreign universities, research institutes, factories, as well as industries such as petrochemicals, smelting, casting, mechanical manufacturing, and military industry. Our products have been exported to more than 20 countries and regions around the world, Including Asia,Africa,America and other regions, as well as Martinique,Coral Sea Islands,Chile,Malta,Sweden,Poland, and other countries.

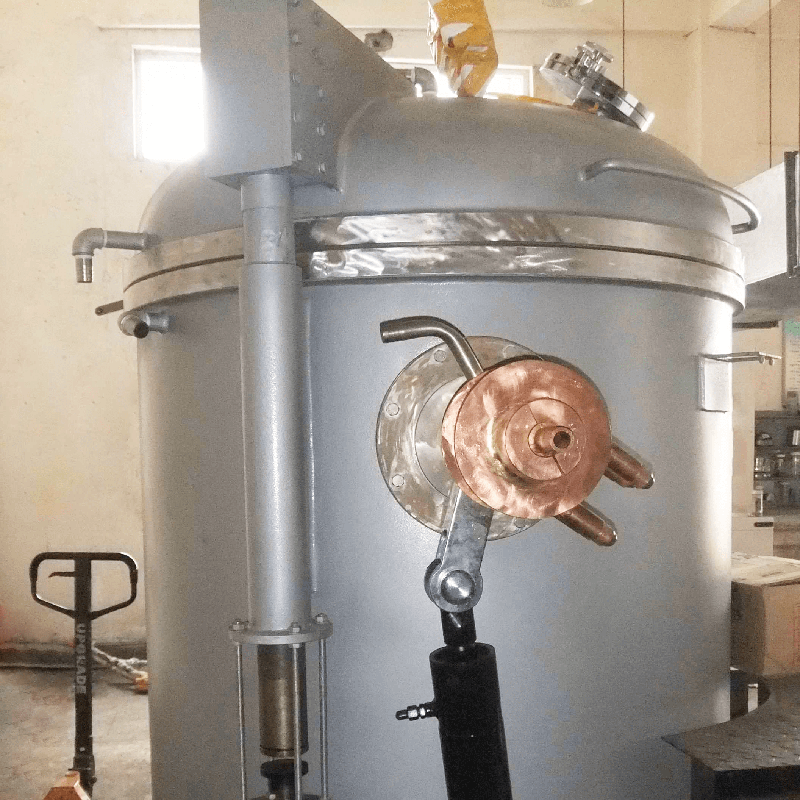

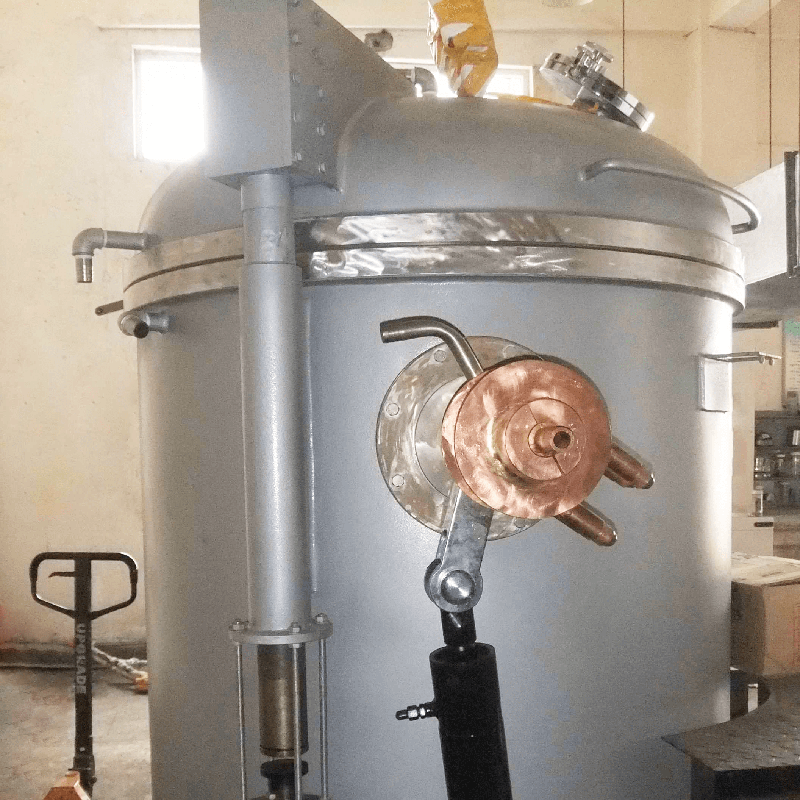

| Product name | electric kiln furnace |

| Place of Origin | Shandong,China |

| Machinery Test Report | Provided |

Product Type

| Induction Furnace

|

| Warranty of core components | 1Year

|

Condition

| New |

Core Components

| PLC, Engine, Gear

|

Packing Size(cm)

| 359*218*271 Specific consultation with us

|

| Brand Name | Kehua

|

Export region

| Oceania,America,Asia Europa Island,United States of America,Azerbaijan,Jamaica,Niue

|

Weight(kg)

| 4213

|

Power (kW)

| It depends

|

Key Selling Points

| Easy to Operate

|

Voltage

| 110V/220V/380V

|

After Warranty Service

| Video technical support

|

After-sales Service

| Provided Online Support

|

Video outgoing-inspection

| Provided

|

Packaging Details

| Polyfoam filled, Wooden box outside

|

Supply Ability

| 20-100 Set/Sets per Month (See specific model products) |

Lead time (days)

| 40 (To be negotiated)

|

Please note: This table is for reference only, please consult us for specific information.

electric kiln furnace is an electric heating device that utilizes electrical energy to generate high temperatures and heat them. Its main working principle is to convert electrical energy into thermal energy, and transfer the thermal energy to the heating material through heating elements, thereby heating it up.

Consisting of a power connector, electronic controller, heating element, and housing. The power connector supplies electrical energy to the electronic controller, which controls the operation of the heating element based on the required temperature setting and actual temperature situation of the heating material.

After-sales Service Provided Free spare parts, installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support.

electric kiln furnace---FAQs Guide

1.About electric kiln furnace,how about your company's certification?

The company has passed ISO9001 quality certification and CE certification.

2.As a electric kiln furnace manufacturer,how can we guarantee quality?

Ensure the excellent performance and accuracy of our product line by controlling, inspecting and improving the optimized quality mechanism of our products.All our products have undergone various quality tests to ensure that they comply with the specifications and standards stipulated by the industry.

3.As a electric kiln furnace manufacturer,do you accept OEM?

Yes, we accept OEM, it would be better if you can provide detailed drawings or pictures.

4.What is the electricity consumption of an electric kiln furnace?

The electricity consumption of an electric furnace depends on the size and efficiency of the furnace. Generally, electric furnaces range from 5,000 to 50,000 watts, with an average of about 25,000 watts.

5.How does an electric kiln furnace utilize resistance to generate heat?

An electric kiln furnace utilizes resistance to generate heat by passing an electric current through a heating element, usually made of metal. The resistance of the metal causes it to heat up, and the heat is then transferred to the air in the furnace.

6.As a electric kiln furnace manufacturer,do you provide other supporting tools besides medium frequency induction furnace, and what are them?

Yes, according to the customer requirements, we provide the following supporting tools:

a).Transformer

b) Push-out lining system

c) Loading cell system

d).Charging system for solid material

e).Deslag system

f). Emergency diesel generator

7.What is the shell material of the electric kiln furnace?

The shell material of an electric kiln furnace typically consists of steel, stainless steel, or cast iron.

8.What is the temperature range of this electric kiln furnace?

The temperature range of an electric furnace typically ranges from 50°F to 90°F.

9.Does this electric kiln furnace have the characteristic of silent operation?

No, electric kiln furnace do not typically have the characteristic of silent operation.

10.What are the heating elements of an electric furnace?

The heating elements of an electric furnace are typically made of metal coils or rods that are heated by electricity. The heated coils or rods then transfer the heat to the air that is circulated throughout the home.

11.How much space can this electric kiln furnace provide enough heat?

The amount of space an electric kiln furnace can provide enough heat for depends on the size and power of the furnace. Generally, a furnace with a capacity of 40,000 BTU can provide enough heat for a space of up to 1,500 square feet.

Tags:total electric furnace,quantum electric arc furnace,electric central furnace,electric lead melting furnace,electric heating furnace,post weld heat treatment furnace,conforto electric furnace