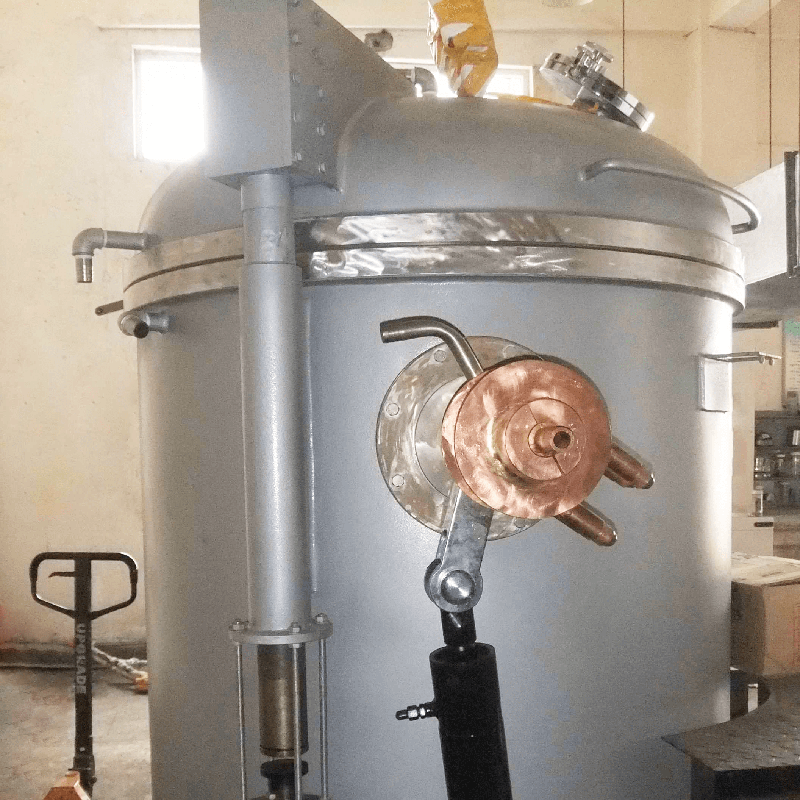

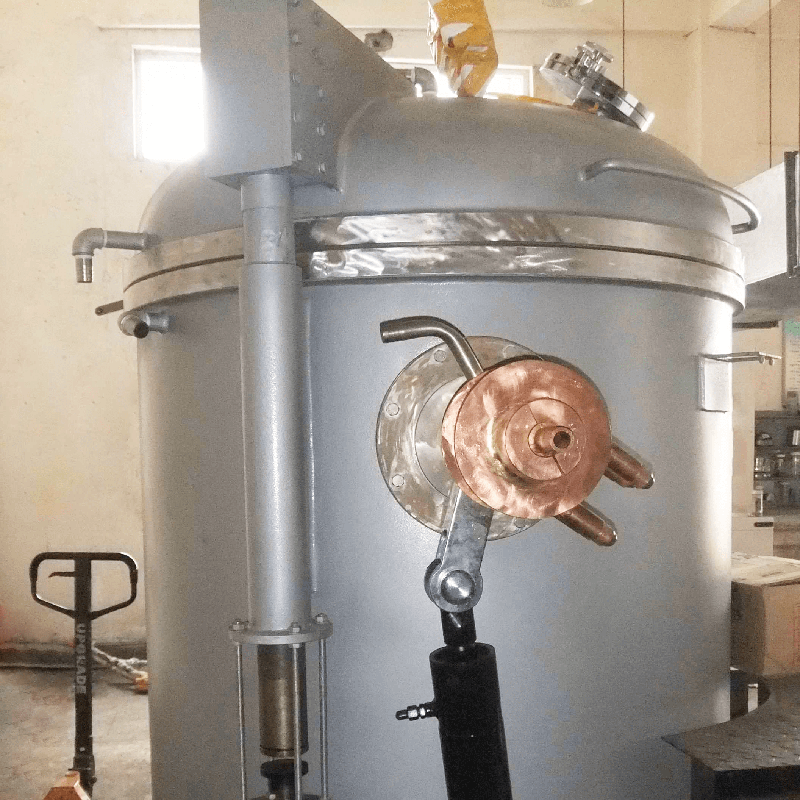

Kehua Intellient Equipment is a professional manufacturer for medium frequency induction melting and heating equipmets, mainly producing intelligent mobile bottom furnaces,smelting furnaces,electric furnaces,high-temperature furnaces,industrial room furnaces,vacuum furnaces,melting furnace,water-cooled pumps,tube furnaces and other products.We have modern infrastructure and expert professionals who help us develop test equipment according to the exact requirements of customers. Ensure the excellent performance and accuracy of our product line by controlling, inspecting and improving the optimized quality mechanism of our products. We have always been committed to innovating products, focusing on long-term customer relations, and constantly strive to improve the quality of our products and deliver goods on time.

All our products have undergone various quality tests to ensure that they comply with the specifications and standards stipulated by the industry. In addition, our quality control experts pay close attention to the whole process from production to scheduling to provide a quality range approved by certification standards such as ISO 9001 and ISO 14001:2015.

| # | electric furnace metal melting Parameter | Information

|

| 1 | Product catalog: | Induction Furnace

|

| 2 | Material:

| Stainless steel, heat-resistant steel, refractory materials, etc

|

| 3 | Usage: | Processing of plastic materials,Manufacturing of sealing materials,Biomedical field,Melting scrap metal,Casting and forging |

| 4 | Color:

| Customized

|

| 5 | Place of Origin:

| Weifang, Shandong

|

| 6 | Packing:

| Standard export packing

|

| 7 | Marketing Type: | Ordinary Product

|

| 8 | Quality Guarantee:

| 1 year

|

| 9 | Brand Name:

| Kehua

|

| 10 | Export region:

| Oceania,Asia,Africa

Honduras,Belarus,Togo,Tajikistan,Bosnia and Herzegovina

|

| 11 | Order Lead Time:

| 30-40 days after the order is confirmed

|

| 12 | Packing size(cm):

| 368*203*265 Specific consultation with us

|

| 13 | OEM/ODM:

| Acceptale

|

| 14 | MOQ: | 1 set |

| 15 | Certificate: | ISO90001 |

| 16 | Weight(kg):

| 2013

|

| 17 | Key Selling Points:

| Automatic

|

| 18 | After-sales service:

| Provide assembly and commissioning, training and eliminate risks, one stop solution to your worries

|

| 19 | Video outgoing-inspection

| Provided

|

| 20 | Voltage

| 110V/220V/38V |

Please note: This table is for reference only, please consult us for specific information.

The product has characteristics such as high safety, durability, high efficiency, and convenient maintenance.The power cabinet is also equipped with a smelting manager. PLC and man-machine interface constitute a convenient operation of the smelting manager, the functions include: cold furnace start,fault information display and storage,fault diagnosis,automatic furnace start,system status display, etc.

There are many different types of electric furnace metal melting, and their working methods often vary slightly. These furnaces have three to six resistance heating elements, each ranging from 3.5 to 7 kW. The working principle of these heating elements is very similar to the heating elements in a toaster. Charged particles move through metal wires, generating heat. The heating element is made of long wires, which are wound into coils and installed in the furnace.

After-sales Service Provided Free spare parts, installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support.

electric furnace metal melting---FAQs Guide

1.Does the electric furnace metal melting provide multiple heating modes or settings?

Yes, most electric furnaces provide multiple heating modes or settings. These settings can include low, medium, and high heat settings, as well as fan-only settings. Some electric furnaces also offer additional features such as programmable thermostats, energy-saving settings, and zone control.

2.Is the digital display screen of the electric furnace metal melting easy to read?

Yes, most digital display screens on electric furnaces are designed to be easy to read.

3.If I purchase your electric furnace metal melting,can I have my logo on the machine?

Yes, of course. We can not only offer standard machines, but also customized machines according to your requirements. And we can also put your logo on the machine.

4.What accessories are included in the packaging of electric furnace metal melting products?

The accessories included in the packaging of electric furnace products typically include a furnace, a thermostat, a blower, a filter, a vent pipe, a vent cap, a wiring harness, and installation instructions.

5.Does the electric furnace metal melting require regular maintenance?

Yes, electric furnace metal melting require regular maintenance to ensure they are running efficiently and safely. Maintenance should include cleaning and inspecting the furnace, checking the thermostat, and replacing the air filter.

6.Do electric furnace metal melting have different appearances or colors?

No, electric furnaces typically have a standard appearance and color.

7.Are you a electric furnace metal melting manufacturer or a electric furnace metal melting trading company?

We are professional intelligent induction heating equipment manufacturer,we have our own research and development team and factory, we have mature technical experience to guarantee the quality of products and optimal price.

8.Is the performance of the electric furnace metal melting affected by temperature changes?

Yes, the performance of an electric furnace metal melting can be affected by temperature changes. Temperature changes can affect the efficiency of the furnace, as well as the amount of heat produced. Additionally, temperature changes can cause the furnace to overheat, leading to potential safety hazards.

9.Is the installation process of the electric furnace metal melting complex?

The installation process of an electric furnace metal melting can vary depending on the type of furnace and the complexity of the installation. Generally, the installation process involves connecting the furnace to the power supply, mounting the furnace, connecting the ductwork, and testing the furnace. In some cases, additional steps may be required, such as installing a thermostat or other controls.

10.How does this electric furnace metal melting work in conjunction with a temperature controller?

An electric furnace works in conjunction with a temperature controller by using the temperature controller to regulate the temperature of the furnace. The temperature controller will monitor the temperature of the furnace and adjust the power output of the furnace accordingly. This allows the furnace to maintain a consistent temperature, which is important for efficient operation. The temperature controller can also be used to set the desired temperature of the furnace, allowing the user to customize the temperature of the furnace to their needs.

11.Are there different types of electric furnace metal melting heating elements available for selection?

Yes, there are several types of electric furnace heating elements available for selection. These include resistance wire elements, cartridge elements, strip elements, and tubular elements. Each type of element has its own advantages and disadvantages, so it is important to select the right type for the specific application.

12.What are the safety features of electric furnace?

Being one of the top electric furnace metal melting manufacturers in China, We attach great importance to this detail.

1. Overheat Protection: Electric furnaces are equipped with an overheat protection system that will shut off the furnace if it gets too hot.

2. Flame Sensor: Electric furnaces are equipped with a flame sensor that will shut off the furnace if it detects a flame.

3. Carbon Monoxide Detector: Electric furnaces are equipped with a carbon monoxide detector that will shut off the furnace if it detects dangerous levels of carbon monoxide.

4. Ground Fault Circuit Interrupter: Electric furnaces are equipped with a ground fault circuit interrupter (GFCI) that will shut off the furnace if it detects an electrical fault.

5. Pressure Switch: Electric furnaces are equipped with a pressure switch that will shut off the furnace if it detects a pressure drop.

6. Flame Rollout Switch: Electric furnaces are equipped with a flame rollout switch that will shut off the furnace if it detects a flame rolling out of the burner.

13.What are the advantages of electric furnace compared to traditional gas or oil furnaces?

Our electric furnace metal melting products undergo strict quality control to ensure customer satisfaction.

1. Lower Operating Costs: Electric furnaces are more energy efficient than traditional gas or oil furnaces, resulting in lower monthly energy bills.

2. Cleaner Burning: Electric furnaces do not produce any emissions, making them a much cleaner burning option than traditional gas or oil furnaces.

3. Quieter Operation: Electric furnaces are much quieter than traditional gas or oil furnaces, making them a great option for those who want a quieter home.

4. Longer Lifespan: Electric furnaces typically have a longer lifespan than traditional gas or oil furnaces, meaning you won’t have to replace them as often.

5. Easier Maintenance: Electric furnaces require less maintenance than traditional gas or oil furnaces, making them a great option for those who don’t want to spend a lot of time and money on maintenance.

Tags:electric furnace 15kw,large vacuum furnace,electric furnace menards,custom vacuum furnace