Shandong Kehua Intellient Equipment is a manufacturer specializing in medium frequency induction melting and heating equipment. Its products cover water-cooled pumps,tube furnaces,electric furnaces,industrial room furnaces,melting furnace,induction furnace,elevator furnaces,heat treatment furnace,intelligent mobile bottom furnaces, etc. We provide customers with a one-stop solution. Our products have been exported to more than 20 countries and regions around the world, and have received high recognition from customers.For example: Oceania,Asia,America and other regions, as well as Tuvalu,Saint Kitts and Nevis,Juan de Nova Island,Belarus,Antarctica,Faroe Islands,Slovenia and other countries.

| Product name | electric furnace heat strips |

| Place of Origin | Weifang, Shandong, China |

| Machinery Test Report | Provided |

Product Type

| Induction Furnace

|

| Warranty of core components | 12 Month

|

Condition

| New |

Core Components

| Furance,Vacuum Pump

|

Packing Size(cm)

| 416*185*321 Specific consultation with us

|

| Brand Name | Kehua

|

Export region

| Oceania,America,Africa Antarctica,Namibia,Andorra,Albania,Croatia

|

Weight(kg)

| 2527

|

Power (kW)

| It depends

|

Key Selling Points

| High quality

|

Voltage

| 110V/220V/380V

|

After Warranty Service

| Video technical support

|

After-sales Service

| Video technical support, Online support

|

MOQ

| 1 set

|

Packaging Details

| Polyfoam filled, Wooden box outside

|

Supply Ability

| 10-20 Set/Sets per Month (See specific model products) |

Lead time (days)

| 30-40 (To be negotiated)

|

Please note: This table is for reference only, please consult us for specific information.

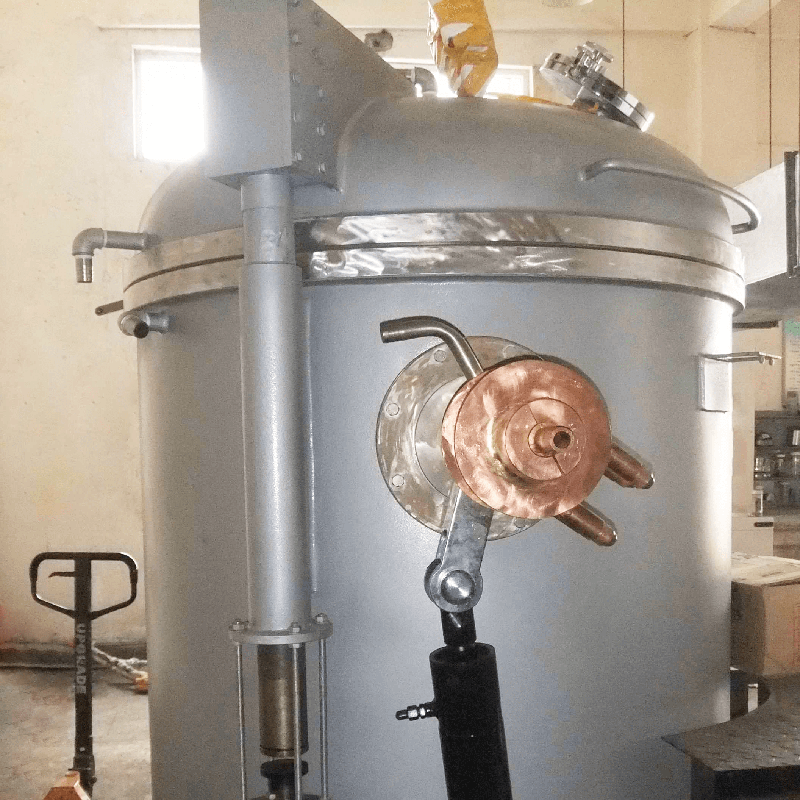

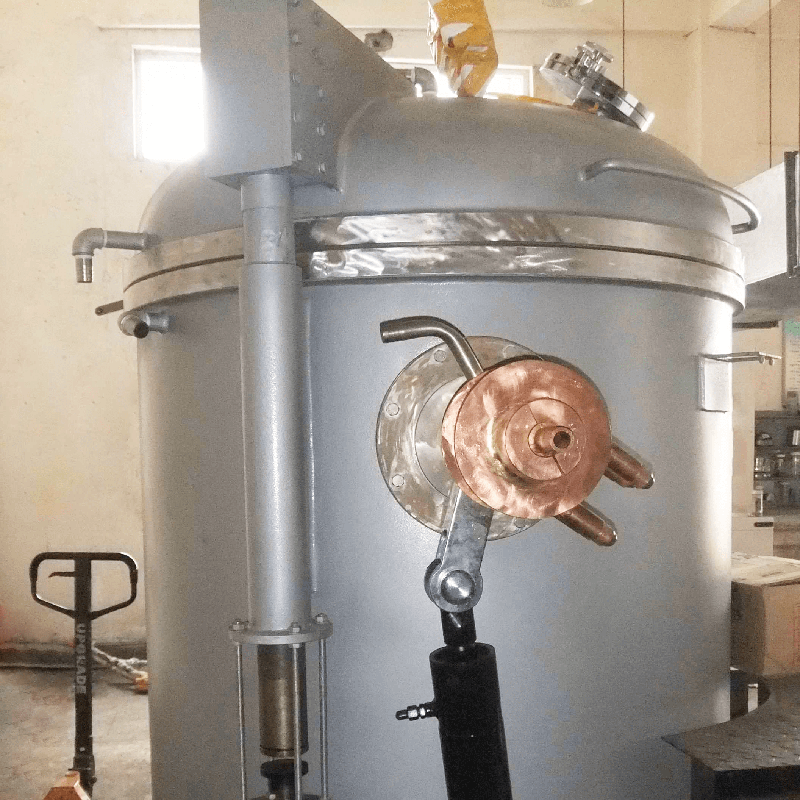

The product has characteristics such as high safety, durability, high efficiency, and convenient maintenance.The power cabinet is also equipped with a smelting manager. PLC and man-machine interface constitute a convenient operation of the smelting manager, the functions include: operation information display,fault information display and storage,fault diagnosis,system status display,automatic furnace start, etc.

There are many different types of electric furnace heat strips, and their working methods often vary slightly. These furnaces have three to six resistance heating elements, each ranging from 3.5 to 7 kW. The working principle of these heating elements is very similar to the heating elements in a toaster. Charged particles move through metal wires, generating heat. The heating element is made of long wires, which are wound into coils and installed in the furnace.

After-sales Service Provided Free spare parts, installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support.

electric furnace heat strips---FAQs Guide

1.As a electric furnace heat strips manufacturer,do you provide other supporting tools besides medium frequency induction furnace, and what are them?

Yes, according to the customer requirements, we provide the following supporting tools:

a).Transformer

b) Push-out lining system

c) Loading cell system

d).Charging system for solid material

e).Deslag system

f). Emergency diesel generator

2.What material is the heating element of this electric furnace usually made of?

The heating element of an electric furnace is typically made of a nickel-chromium alloy, such as Nichrome.

3.Does this electric furnace heat strips comply with international electrical safety standards?

It depends on the specific electric furnace and the international electrical safety standards in question. It is best to consult the manufacturer of the electric furnace to determine if it complies with the relevant standards.

4.Do electric furnace heat strips have different appearances or colors?

No, electric furnaces typically have a standard appearance and color.

5.About electric furnace heat strips,how about your company's certification?

The company has passed ISO9001 quality certification and CE certification.

6.What is the starting and stopping process of an electric furnace heat strips?

The starting process of an electric furnace heat strips involves turning on the power switch, setting the thermostat, and allowing the furnace to heat up. The stopping process involves turning off the power switch and allowing the furnace to cool down.

7.Does this electric furnace heat strips meet environmental standards?

It depends on the specific model and age of the electric furnace. In general, electric furnaces manufactured after 1992 must meet certain environmental standards, such as those set by the Environmental Protection Agency (EPA). It is best to contact the manufacturer of the electric furnace to determine if it meets the necessary standards.

8.Do electric furnace heat strips have energy-saving characteristics?

Yes, electric furnace heat strips can have energy-saving characteristics. Many electric furnaces are designed with energy-saving features such as variable speed blowers, two-stage heating, and programmable thermostats. These features can help reduce energy consumption and lower energy bills.

9.How does an electric furnace heat strips utilize resistance to generate heat?

An electric furnace heat strips utilizes resistance to generate heat by passing an electric current through a heating element, usually made of metal. The resistance of the metal causes it to heat up, and the heat is then transferred to the air in the furnace.

10.Is there a remote monitoring or alarm system for the electric furnace heat strips?

Yes, there are several remote monitoring and alarm systems available for electric furnaces. These systems can be used to monitor the temperature, humidity, and other conditions in the furnace, as well as alert you to any potential problems.

11.As a electric furnace heat strips manufacturer,do you accept OEM?

Yes, we accept OEM, it would be better if you can provide detailed drawings or pictures.

12.About electric furnace heat strips, how about the warranty?

We provide assembly and debugging, training, and risk elimination to address your concerns in a one-stop shop. Quality assurance: 1 year. Provide free accessories during the warranty period; After the warranty period, timely provision of accessories, discounted prices, and guidance on installation and debugging.

13.How does the temperature control system of an electric furnace heat strips work?

The temperature control system of an electric furnace works by using a thermostat to measure the temperature of the air inside the furnace. The thermostat then sends a signal to the furnace's control board, which in turn activates the heating elements to increase or decrease the temperature as needed. The control board also monitors the temperature and will shut off the heating elements when the desired temperature is reached.

14.As a electric furnace heat strips manufacturer,how is the package of the goods ? Delivery methods?

According to the specific conditions of the equipment, it is packed in a fumigation-free wooden box, PVC wrapping film and plastic woven cloth. Sea shipping and railway transport for whole set of the equipment as well as Express according to customer requirements, find the most suitable way.

15.What different industrial fields can electric furnace be applied to?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services.

Electric furnaces can be used in a variety of industrial fields, including:

1. Metalworking: Electric furnaces are used to melt and alloy metals, such as steel, aluminum, and copper.

2. Ceramics: Electric furnaces are used to fire ceramic products, such as pottery and tiles.

3. Glassmaking: Electric furnaces are used to melt and shape glass products.

4. Refractory: Electric furnaces are used to produce refractory materials, such as bricks and insulation.

5. Petrochemical: Electric furnaces are used to refine and process petroleum products.

6. Heat Treatment: Electric furnaces are used to heat treat metals and alloys.

7. Food Processing: Electric furnaces are used to dry and process food products.

16.Does the electric furnace heat strips have intelligent fault diagnosis function?

Yes, many electric furnace heat strips have intelligent fault diagnosis functions. This feature allows the furnace to detect and diagnose any potential problems and alert the user to take corrective action.

Tags:electric versus gas furnace,fluidized bed heat treatment furnaces,induction crucible melting furnace,small vacuum furnace,reducing electric furnace,10 kw electric furnace,electric furnace components