Melting furnaces play a crucial role in industries that involve the processing of metals and alloys. These powerful devices are designed to melt various types of metals, allowing them to be molded, cast, or refined into new shapes and products. As industries grow and evolve, the demand for efficient, reliable, and high-performance melting furnaces continues to rise. Kehua, a leading manufacturer of industrial equipment, specializes in producing state-of-the-art melting furnaces that meet the rigorous demands of modern industry. In this article, we will explore the advantages of using melting furnaces, focusing on their efficiency, versatility, and technological advancements.

Efficiency and Performance

One of the primary advantages of using a melting furnace is its high efficiency in melting metals. Kehua’s melting furnaces are engineered to provide rapid and uniform heating, ensuring that the metal reaches the desired temperature quickly and evenly. For example, the Kehua KF-1000 model can reach temperatures of up to 1600°C within minutes, significantly reducing the time needed to process metals.

This efficiency translates to lower energy consumption and reduced operational costs. The use of advanced insulation materials in Kehua’s furnaces minimizes heat loss, ensuring that more energy is used for melting rather than being wasted. This not only saves on energy bills but also contributes to a more sustainable operation by reducing the overall carbon footprint.

Versatility and Flexibility

Kehua’s melting furnaces are designed to handle a wide range of metals, including aluminum, brass, copper, silver, and gold. This versatility makes them ideal for various industries, from metal casting and foundries to jewelry making and recycling plants. The ability to process different metals in the same furnace without compromising on quality or efficiency is a significant advantage, especially for businesses that deal with multiple types of metals.

The KF-2000 model, for example, is equipped with interchangeable crucibles, allowing users to switch between different metals with ease. This flexibility is crucial for industries that require frequent changes in production or need to process various materials simultaneously.

Precision and Control

Another significant advantage of Kehua’s melting furnaces is the level of precision and control they offer. Accurate temperature control is essential in metal processing to ensure the quality and integrity of the final product. Kehua’s furnaces feature advanced temperature controllers that allow users to set and maintain precise temperatures throughout the melting process.

The KF-3000 model, for instance, includes a digital control system with a temperature accuracy of ±1°C. This high level of precision ensures that the metal is melted at the optimal temperature, preventing issues such as overheating or incomplete melting, which can lead to defects in the final product.

Durability and Longevity

Kehua’s melting furnaces are built to last, with robust construction and high-quality materials that withstand the demanding conditions of industrial use. The use of heat-resistant alloys and advanced refractory materials ensures that the furnace can operate at high temperatures for extended periods without degrading. This durability reduces the need for frequent maintenance and replacement, leading to lower long-term costs.

For example, the KF-4000 model is designed with a reinforced outer shell and a long-lasting heating element that provides consistent performance over many years of operation. This longevity makes Kehua furnaces a reliable investment for any business involved in metal processing.

Technological Advancements

Kehua is committed to integrating the latest technologies into its melting furnaces, ensuring that they remain at the forefront of industrial innovation. Features such as automatic pouring systems, programmable melting cycles, and real-time monitoring enhance the functionality and ease of use of the furnaces.

The KF-5000 model, for example, includes a touch-screen interface that allows operators to monitor the entire melting process, adjust parameters, and receive alerts in case of any issues. These technological advancements not only improve productivity but also enhance safety by reducing the likelihood of human error.

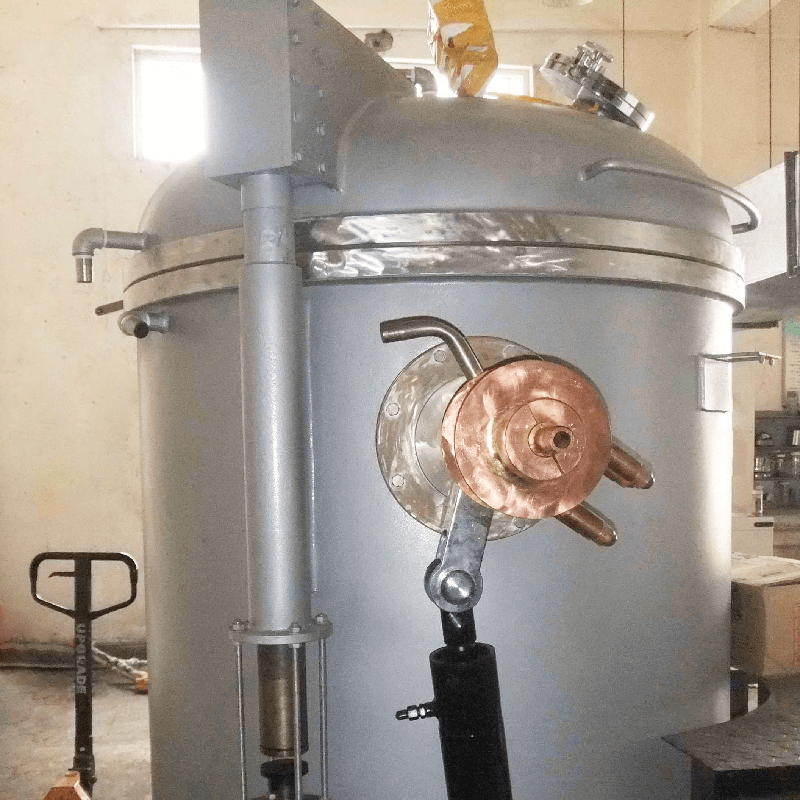

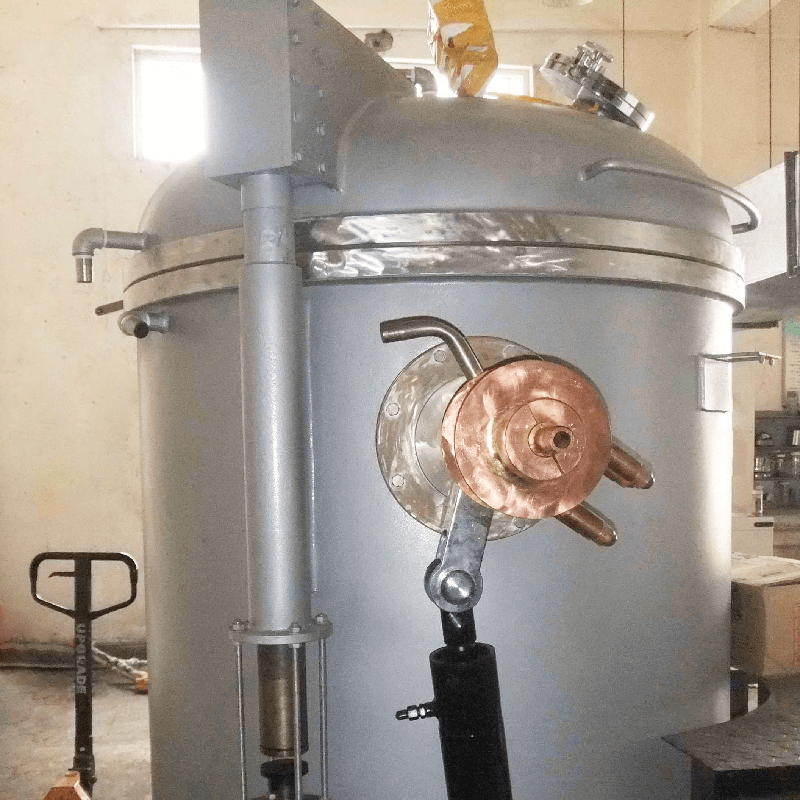

Product: Vacuum Induction Melting Furnace

Q&A Section

1. What types of metals can be melted in Kehua’s furnaces?

Kehua’s melting furnaces are designed to melt a wide variety of metals, including aluminum, brass, copper, silver, gold, and more. Models like the KF-2000 are equipped with interchangeable crucibles, allowing for easy processing of different metals.

2. How precise is the temperature control in Kehua’s melting furnaces?

Kehua’s melting furnaces, such as the KF-3000 model, feature advanced digital control systems that provide temperature accuracy within ±1°C. This high level of precision ensures optimal melting conditions and high-quality outputs.

3. What are the energy efficiency benefits of using Kehua’s melting furnaces?

Kehua’s melting furnaces are designed for high efficiency, with advanced insulation materials and rapid heating capabilities. For example, the KF-1000 model can reach temperatures of up to 1600°C quickly, reducing energy consumption and operational costs.

In conclusion, Kehua’s melting furnaces offer numerous advantages, including high efficiency, versatility, precision, durability, and technological innovation. These features make them an ideal choice for industries involved in metal processing, ensuring reliable and high-quality results while minimizing costs and energy use. Whether you are in metal casting, recycling, or jewelry making, Kehua’s melting furnaces provide the performance and reliability you need to succeed.