Heat treatment furnaces are essential units in many industries that involve metal processing. These furnaces play a crucial role in enhancing the mechanical properties of metals such as strength, hardness, and durability. The process of heat treatment involves carefully heating and cooling a metal in a controlled environment to modify its properties, making it suitable for specific applications.

Working Principle of Heat Treatment Furnaces:

The working principle of heat treatment furnaces is based on the fundamental concept of heat transfer. The furnace provides controlled heat energy to the metal, which alters its microstructure, resulting in desired material properties. This heat energy is typically achieved through electric or gas-fired heating elements, which generate temperatures ranging from 700 ͦC to 1200 ͦC, depending on the type of metal and the required treatment.

The Process of Heat Treatment:

The process of heat treatment involves three main stages: heating, holding, and cooling. Firstly, the metal is heated to a specific temperature, which is determined by the type of metal and the desired properties. The furnace's heating system is designed to provide a uniform and gradual temperature rise to prevent thermal shock, which can cause cracks and distortions. Once the metal reaches the desired temperature, it is held at that temperature for a specified time. This stage is critical as it allows for the desired transformation of the metal's microstructure. Finally, the metal is slowly cooled at a controlled rate, depending on the type of treatment required. This cooling process is also essential as it allows the metal to reach its final properties without causing excess stress.

Types of Heat Treatment Furnaces:

There are various types of heat treatment furnaces, and the type used depends on the material being treated and the desired properties. Some of the most common types of heat treatment furnaces include:

1. Batch Furnaces:

Batch furnaces are the most commonly used type of heat treatment furnaces. They are designed to accommodate a single batch of material at a time and are suitable for small-scale production. Batch furnaces are versatile and can be used for a variety of purposes such as annealing, hardening, and tempering.

2. Continuous Furnaces:

As the name suggests, continuous furnaces allow for the continuous processing of materials without the need for frequent loading and unloading. These furnaces are designed for mass production and are typically used in large-scale industrial applications. The materials are loaded onto a conveyor belt, which moves through the furnace, ensuring a constant flow of workpieces.

3. Vacuum Furnaces:

Vacuum furnaces are designed to eliminate the effects of oxidation that can occur during the heating process. These furnaces provide a controlled environment with a low oxygen level, preventing chemical reactions that can affect the metal's properties. Vacuum furnaces are commonly used in applications where the metal needs to have a clean and bright surface after treatment.

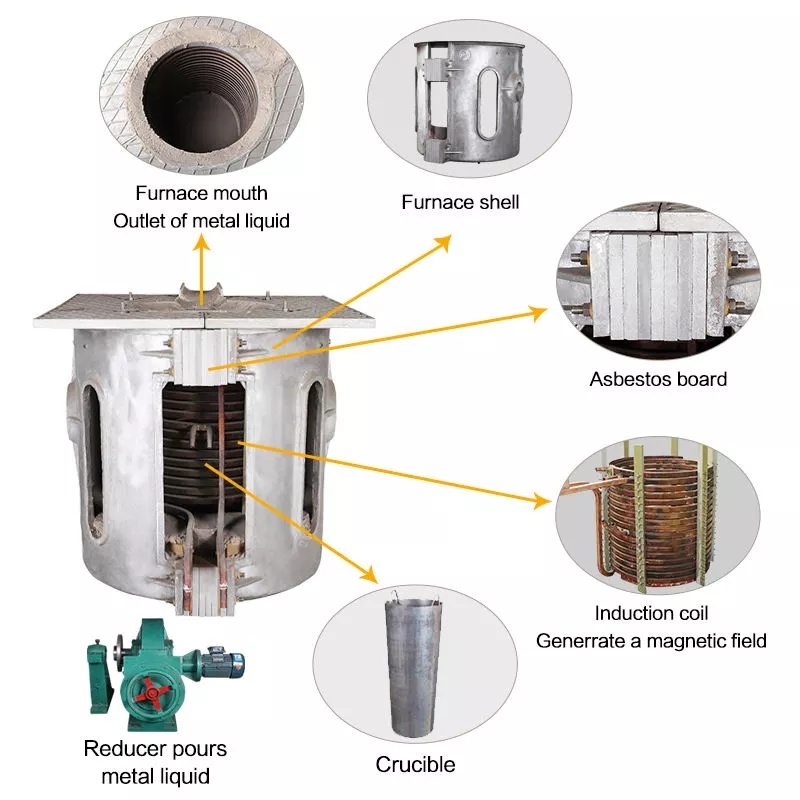

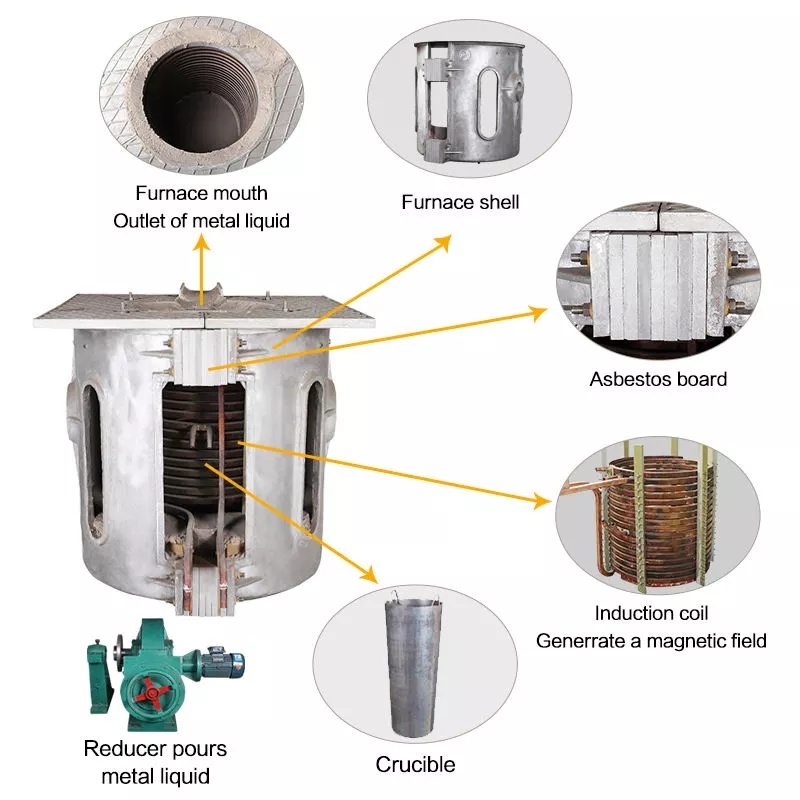

4. Induction Furnaces:

Induction furnaces use electromagnetic induction to create heat energy. These furnaces have a coil that generates a magnetic field, and the workpiece is placed inside this field. As the workpiece heats up, it also induces an electric current within itself, creating heat energy. Induction furnaces are ideal for heating small and complex shapes, making them suitable for precision heat treatment applications.

5. Salt-Bath Furnaces:

Salt-bath furnaces use molten salt as the heating medium. The workpiece is immersed in the salt, which is heated to the desired temperature using electric currents or gas burners. Salt-bath furnaces are particularly useful for treating small and intricate parts, and they offer a high degree of control over the heating process.

Heat treatment furnaces are essential equipment in industries such as aerospace, automotive, and tool manufacturing. These furnaces work by providing controlled heat energy to metals to alter their microstructure, resulting in improved mechanical properties. There are various types of heat treatment furnaces available, including batch, continuous, vacuum, induction, and salt-bath furnaces, each with its unique features and applications.

Shandong Kehua Intellient Equipment is a leading professional enterprise specializing in the production of electric furnaces and related products. We are committed to meeting the needs of our customers with high-quality products and customized services. With a strong R&D team, we have won a reputation for excellent performance, competitive prices, and timely delivery. We have become a leading furnace manufacturer and exporter in China.

Our products include:electric furnaces,industrial room furnaces,smelting furnaces,water-cooled pumps,elevator furnaces,intelligent mobile bottom furnaces,induction furnace,vacuum furnaces,heat treatment furnace, etc. All of our products have undergone various quality tests to ensure they comply with industry regulations and standards. In addition, our quality control experts closely monitor the entire process from production to scheduling to provide quality ranges approved by certification standards such as ISO 9001 and ISO 14001:2015.

What are the main components of a heat treatment furnace?

The main components of a heat treatment furnace may vary depending on the type and design, but some common elements include:

Heating elements: These are electrically powered devices that generate heat to raise the temperature of the furnace. They can be made from materials such as resistance wires, silicon carbide, or molybdenum disilicide.

Insulation: This is crucial for maintaining high temperatures inside the furnace while keeping the outside cool. Insulation materials such as ceramic fiber or refractory bricks line the inner walls of the furnace.

Fans or blowers: These are used to circulate the heat evenly throughout the furnace, ensuring uniform heating of the metal parts.

Temperature controllers: These devices monitor and regulate the temperature inside the furnace, ensuring that it stays within the desired range for the specific metal and heat treatment process.

What are the benefits of using a heat treatment furnace?

Heat treatment furnaces offer various benefits, such as improving the strength and hardness of materials, enhancing their resistance to corrosion and wear, and increasing their ductility and toughness. They are also used for stress relieving to reduce internal stresses in the material and improve its dimensional stability. Heat treatment can also be used to refine the microstructure of materials, leading to better machinability and surface finish.

What safety precautions should be taken when operating a heat treatment furnace?

When working with a heat treatment furnace, it is essential to take safety precautions to prevent accidents and injuries. Some recommended safety measures include wearing personal protective equipment, such as heat-resistant gloves and goggles, ensuring proper ventilation to avoid exposure to harmful fumes, and regularly inspecting the furnace for any signs of damage or malfunction. It is also crucial to follow the manufacturer's instructions and guidelines for operating the furnace safely.