Induction melting furnace has revolutionized the metallurgical industry, offering unparalleled efficiency, precision, and versatility. As a leading induction melting manufacturer, Kehua is at the forefront of this technological advancement. This article explores the diverse applications of induction melting furnace and how Kehua's state-of-the-art equipment is driving innovation across various sectors.

Introduction to Induction Melting Furnaces

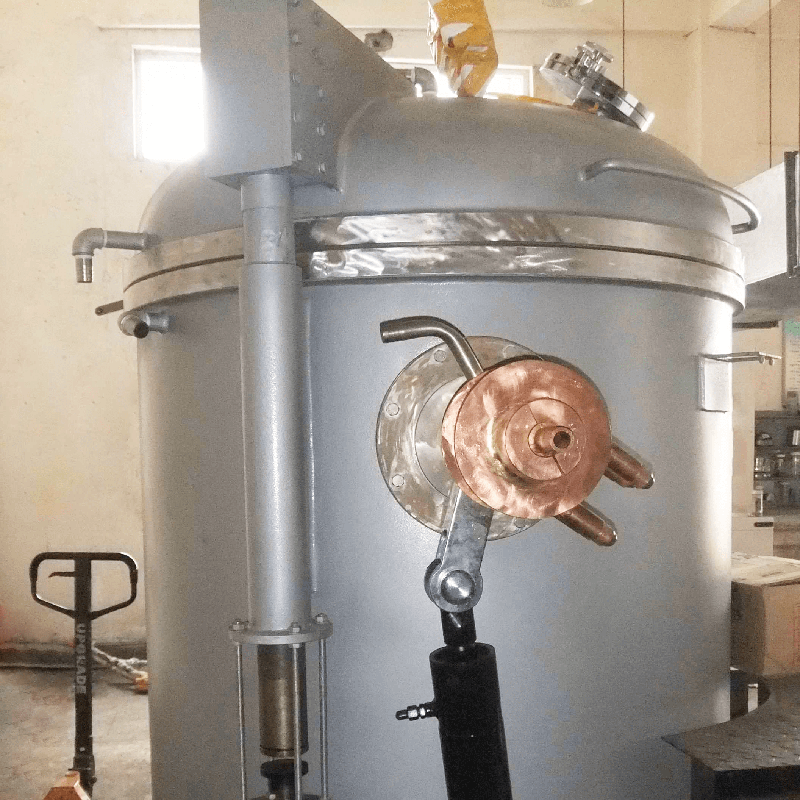

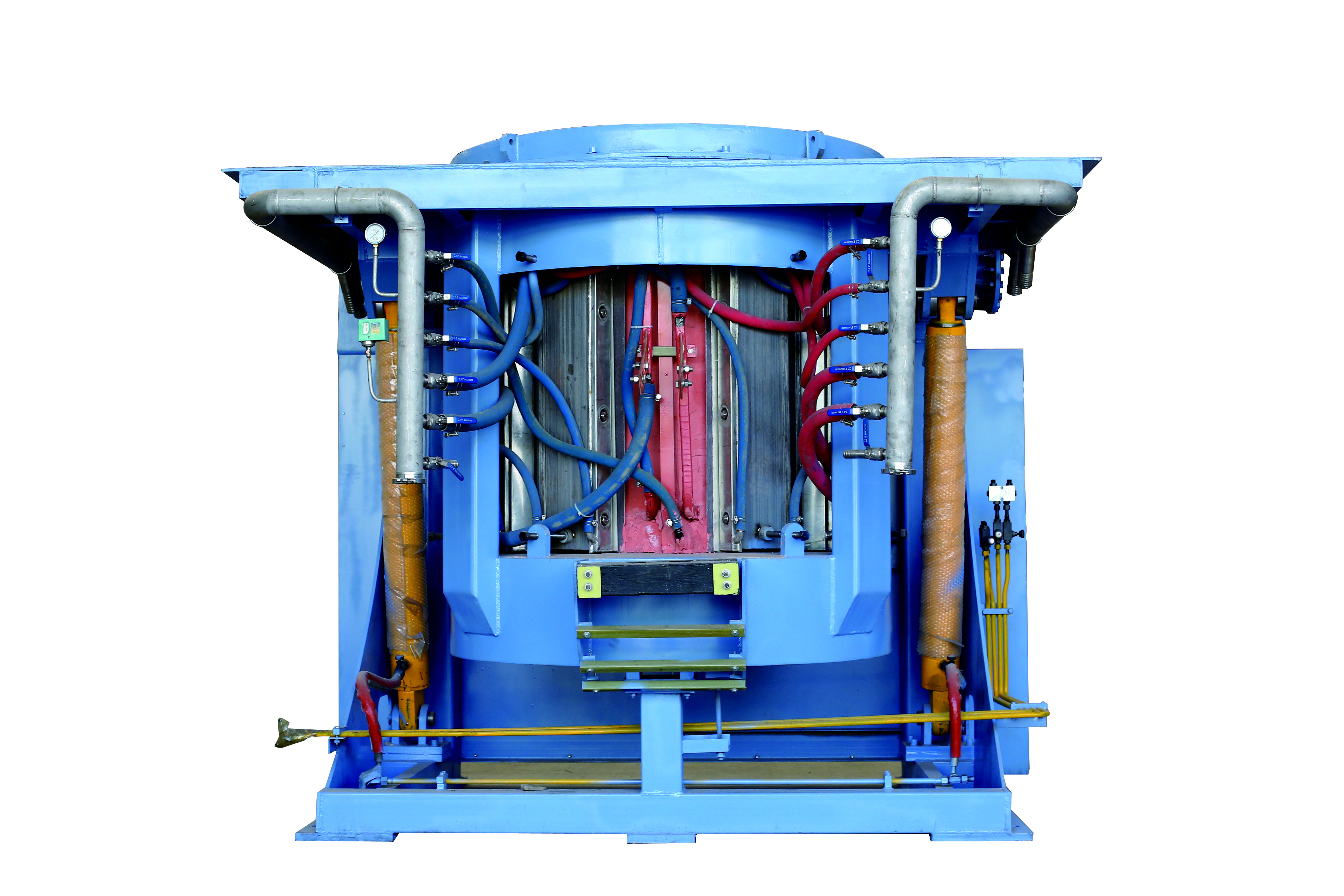

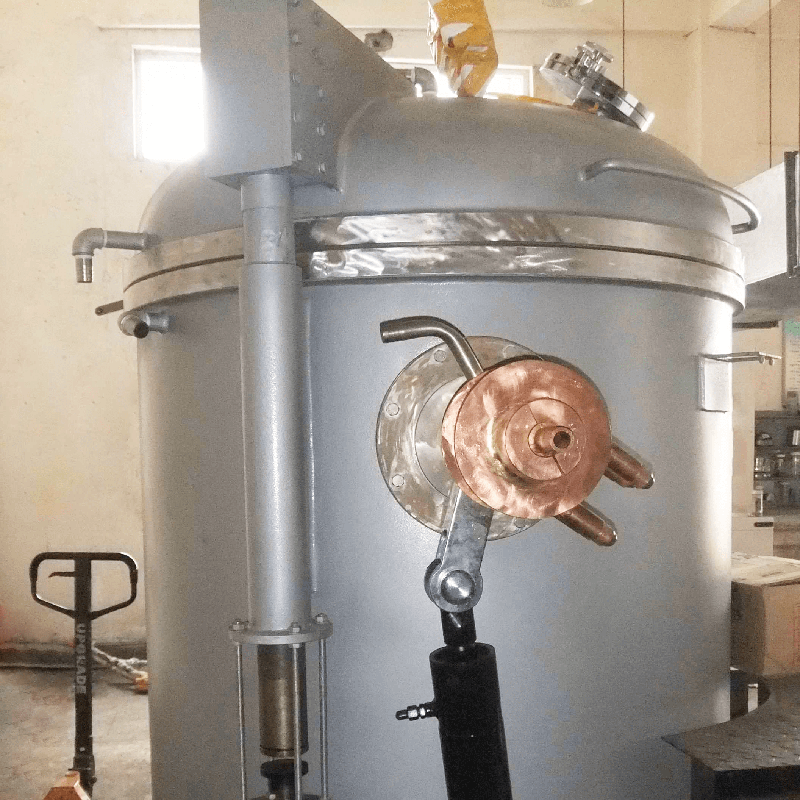

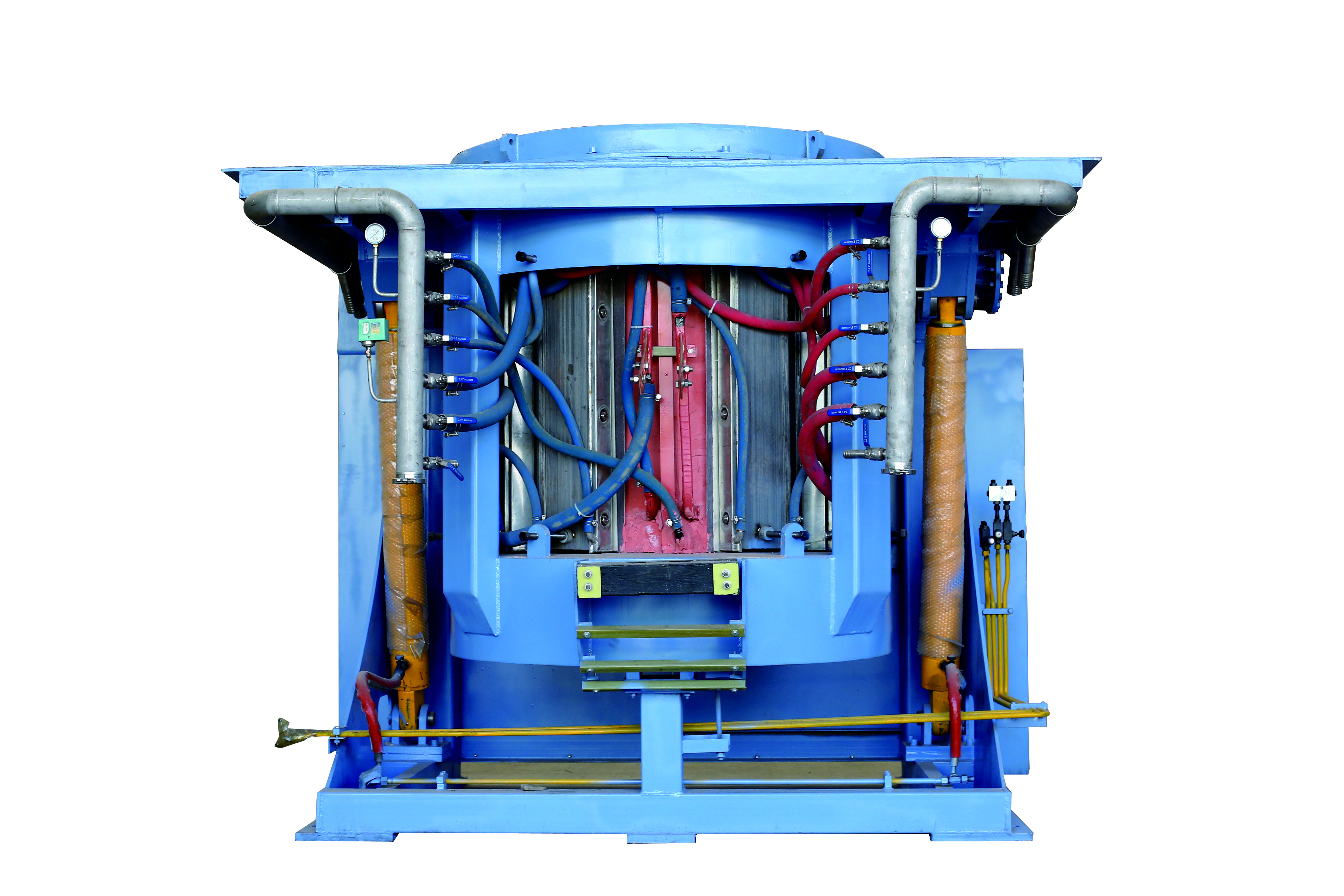

Induction melting furnaces utilize electromagnetic induction to generate heat directly within the metal being melted. This process involves placing the metal in a crucible surrounded by a coil through which an alternating current passes, creating a magnetic field that induces eddy currents within the metal, thereby heating it. This method of heating is highly efficient, as it directly heats the metal without relying on external combustion or resistance elements.

Applications in Various Industries

1. Foundries and Metal Casting

One of the primary applications of induction melting furnaces is in foundries and metal casting operations. These furnaces are used to melt a variety of ferrous and non-ferrous metals, including steel, iron, aluminum, copper, and brass. The precise temperature control offered by Kehua’s induction furnaces ensures consistent melting, which is crucial for producing high-quality castings with minimal defects.

In foundries, induction melting furnaces are used for:

Creating Engine Blocks and Components: The automotive industry relies on high-quality cast iron and aluminum components, which are efficiently produced using induction melting.

Manufacturing Industrial Machinery: Precision casting of parts for heavy machinery and equipment is another key application, ensuring durability and performance.

2. Precious Metals Refining

Induction melting furnaces are also extensively used in the refining of precious metals such as gold, silver, and platinum. The clean, controlled environment provided by these furnaces minimizes contamination, ensuring the purity of the refined metals. This is essential in industries like jewelry manufacturing and electronics, where the quality of precious metals is paramount.

Applications in precious metals refining include:

Jewelry Manufacturing: Melting and alloying of gold and silver for crafting intricate jewelry pieces.

Electronics Industry: Producing high-purity metals for use in electronic components and circuits.

3. Aerospace and Defense

The aerospace and defense industries require materials that can withstand extreme conditions and stresses. Induction melting furnaces play a vital role in producing superalloys and specialized metals used in aircraft engines, turbine blades, and other critical components. The precise control over melting temperatures ensures that these materials meet stringent performance and safety standards.

Key applications include:

Turbine Blade Production: Creating high-strength, heat-resistant alloys for turbine engines.

Structural Components: Producing lightweight, high-strength metals for aircraft frames and defense equipment.

4. Automotive Industry

In the automotive industry, induction melting furnaces are used to produce a wide range of components, from engine parts to brake systems. The ability to rapidly melt and alloy metals makes these furnaces ideal for high-volume production environments.

Applications in the automotive industry include:

Engine Components: Manufacturing of crankshafts, camshafts, and cylinder heads.

Transmission Systems: Producing gears and other transmission components with high precision.

5. Research and Development

Induction melting furnaces are invaluable tools in research and development settings. Their ability to precisely control heating conditions allows scientists and engineers to experiment with new alloys and materials. This capability is crucial for advancing technologies in fields such as materials science, nanotechnology, and renewable energy.

R&D applications include:

Alloy Development: Creating and testing new metal alloys with specific properties.

Material Testing: Conducting experiments to understand the behavior of metals under various conditions.

Advantages of Kehua's Induction Melting Furnaces

1. Energy Efficiency

Kehua's induction melting furnaces are designed for maximum energy efficiency. By directly heating the metal, these furnaces reduce energy losses, resulting in lower operational costs and a smaller environmental footprint. Efficiency ratings can be as high as 98%, significantly outperforming traditional melting methods.

2. Precise Temperature Control

The ability to precisely control the melting temperature is a hallmark of induction melting technology. Kehua’s furnaces offer temperature control within ±1°C, ensuring consistent quality in the melted metal. This precision is critical for applications that demand high standards, such as aerospace and automotive manufacturing.

3. Clean and Safe Operation

Induction melting furnaces provide a clean melting environment, free from the combustion by-products and pollutants associated with other methods. This makes them safer for operators and reduces the need for extensive ventilation systems. Additionally, the risk of contamination is minimized, which is especially important in the refining of precious metals and the production of high-purity alloys.

4. Versatility

Kehua's induction melting furnaces are highly versatile, capable of melting a wide range of metals and alloys. This flexibility makes them suitable for various industries and applications, from large-scale industrial operations to specialized research laboratories.

Induction melting furnaces are a cornerstone of modern metallurgy, offering unmatched efficiency, precision, and versatility. Kehua, as a leading heating equipment manufacturer, provides cutting-edge solutions that drive innovation across multiple industries. Whether in foundries, precious metal refining, aerospace, automotive manufacturing, or research and development, Kehua’s induction melting furnaces deliver the performance and reliability needed to meet the highest standards of quality and efficiency.

Tags: IGBT Medium Frequency Power Supply , Trolley Type Heat Treatment Furnace